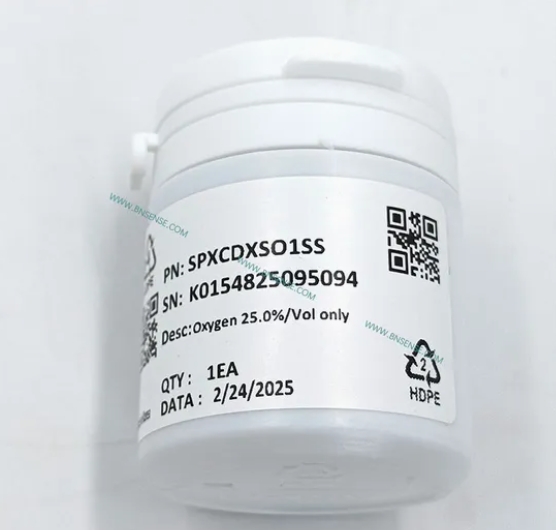

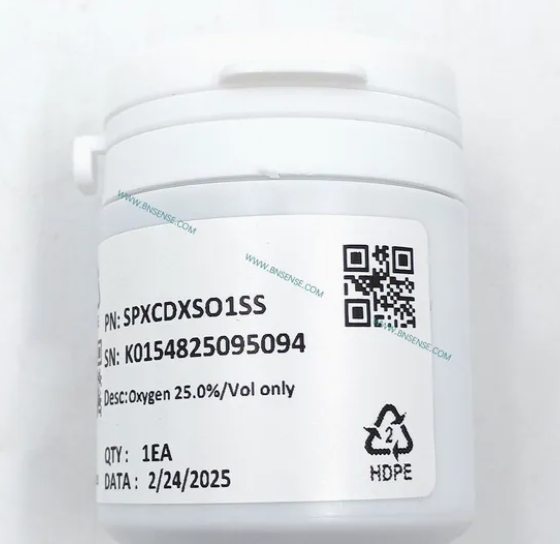

SPXCDXSO1SS

Product Description

The Sensepoint XCD range provides comprehensive monitoring of flammable, toxic and Oxygen gas hazards in potentially explosive atmospheres, both indoors and outdoors. Users can modify detector operation using the LCD and magnet switches without ever needing to open the unit. This enables one-man, non-intrusive operation and reduces routine maintenance time and costs.The Sensepoint XCD comprises a gas detector transmitter and a choice of sensors for detecting flammable gas, toxic gas and oxygen. The construction of Sensepoint XCD allows it to be used in hazardous area locations; it may also be used in other areas not classified as hazardous. The transmitter features a display and three programmable relays for controlling external equipment e.g. alarms, sirens, valves or switches. The transmitter provides an industry standard 3-wire, 4-20 mA source or sink output for connection to a dedicated gas detection control system or

PLC.

Calibration and maintenance are carried out using a Magnetic Wand, this allows a single user to undertake routine maintenance without needing to access internal components.

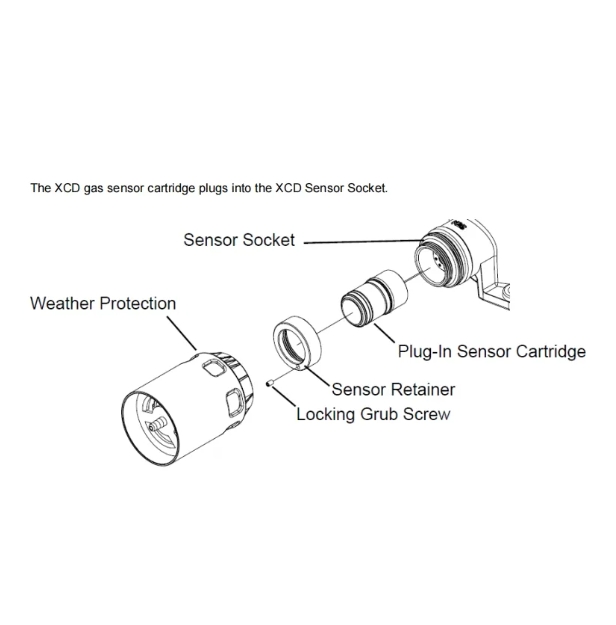

Sensepoint XCD comprises of the main parts as shown below.

Installing the sensor

To install the Sensepoint XCD Sensor Cartridge to the transmitter Sensor Socket:

1. Remove the weather protection (if fitted) from the sensor.

2. Use a 1.5 mm Allen key (hexagonal wrench-included) to loosen the Locking Grub Screw on

the Sensor Retainer.

3. Unscrew and remove the Sensor Retainer.

4. Remove the XCD Sensor Cartridge from its packaging and plug it into the XCD Sensor

Socket, taking care to align the sensor pins with the connector.

5. Refit the Sensor Retainer and tighten the Locking Grub Screw.

6. Refit the weather protection (as required) to the Sensepoint XCD sensor.

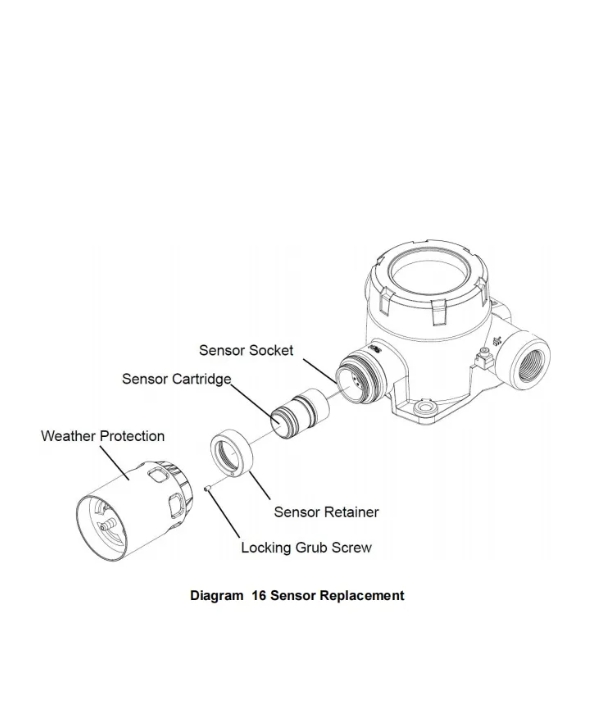

Sensor replacement

The Flammable Catalytic and Toxic ECC sensor cartridges that are used with the Sensepoint XCD

Sensor Socket have no serviceable parts. When they have reached the end of their operational life,

simply replace the sensor cartridge.

To replace the Sensepoint XCD plug-in sensor cartridge use the following procedure:

1. Important: Remove the Power from the Sensepoint XCD Transmitter

2. Remove the Weather Protection or other accessories from the sensor socket thread

3. Loosen the Locking Grub Screw and unscrew the Sensor Retainer

4. Carefully pull the old Sensor from the sensor socket without twisting

5. Fit the new Sensor in its place

6. Calibrate sensor

Ordering information

| Part number | Description |

| Sensepoint XCD transmitter and sensor KIT (ATEX/IECEx/AP*, LM25 and M20 Entry) | |

| SPXCDALMFX | ATEX/IECEx/AP* Methane CAT 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry |

| SPXCDALMRX | ATEX/IECEx/AP* Methane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry |

| SPXCDALMPX | ATEX/IECEx/AP* Propane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry |

| SPXCDALMO1 | ATEX/IECEx/AP* Oxygen 25.0% v/v with LM25, M20 Entry |

| SPXCDALMHX | ATEX/IECEx/AP* Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with LM25, M20 Entry |

| SPXCDALMCX | ATEX/IECEx/AP* Carbon Monoxide 0-500ppm (100 to 1000ppm, 100ppm) with LM25, M20 Entry |

| SPXCDALMG1 | ATEX/IECEx/AP* Hydrogen 0-1000ppm with LM25, M20 Entry |

| SPXCDALNNX | ATEX/IECEx/AP* Nitrogen Dioxide 0-50ppm with Aluminum alloy, M20 Entry |

| SPXCDALMB1 | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-2.00% v/v with LM25, M20 Entry |

| SPXCDALMB2 | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-5.00% v/v with LM25, M20 Entry |

| Sensepoint XCD transmitter and sensor KIT (ATEX/IECEx/AP*, 316SS and M20 Entry) | |

| SPXCDASMFX | ATEX/IECEx/AP* approved Methane CAT 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry |

| SPXCDASMRX | ATEX/IECEx/AP* approved Methane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry |

| SPXCDASMPX | ATEX/IECEx/AP* approved Propane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry |

| SPXCDASMO1 | ATEX/IECEx/AP* approved Oxygen 25.0% v/v with 316SS, M20 Entry |

| SPXCDASMHX | ATEX/IECEx/AP* approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with 316SS, M20 Entry |

| SPXCDASMCX | ATEX/IECEx/AP* approved Carbon Monoxide 0-300ppm (100 to 1000ppm, 100ppm) with 316SS, M20 Entry |

| SPXCDASMG1 | ATEX/IECEx/AP* approved Hydrogen 0-1000ppm with 316SS, M20 Entry |

| SPXCDASNNX | ATEX/IECEX/ AP* approved Nitrogen Dioxide 0-50ppm with SS316, M20 Entry |

| SPXCDASMB1 | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-2.00% v/v with 316SS, M20 Entry |

| SPXCDASMB2 | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-5.00% v/v with 316SS, M20 Entry |

| Sensepoint XCD transmitter and sensor KIT (UL, LM25 and 3/4' NPT Entry) | |

| SPXCDULNFX | UL/cUL approved Methane CAT 0-100%LEL (20 to 100%LEL, 10%LEL) with LM25, 3/4, NPT Entry |

| SPXCDULNRX | UL/cUL approved Methane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with LM25, 3/4, NPT Entry |

| SPXCDULNPX | UL/cUL approved Propane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with LM25, 3/4, NPT Entry |

| SPXCDULNO1 | UL/cUL approved Oxygen 25.0% v/v with LM25, 3/4, NPT Entry |

| SPXCDULNHX | UL/cUL approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with LM25, 3/4, NPT Entry |

| SPXCDULNCX | UL/cUL approved Carbon Monoxide 0-300ppm (100 to 1000ppm, 100ppm) with LM25, 3/4, NPT Entry |

| SPXCDULNG1 | UL/cUL approved Hydrogen 0-1000ppm with LM25, 3/4, NPT Entry |

| SPXCDULNNX | UL approved SP XCD Nitrogen Dioxide 0-50ppm with LM25, 3/4, NPT Entry |

| SPXCDULNB1 | UL/cUL approved Carbon Dioxide IR 0-2.00% v/v with LM25, 3/4, NPT Entry |

| SPXCDULNB2 | UL/cUL approved Carbon Dioxide IR 0-5.00% v/v with LM25, 3/4, NPT Entry |

| Sensepoint XCD transmitter and sensor KIT (UL, 316SS and 3/4, NPT Entry) | |

| SPXCDUSNFX | UL/cUL approved Methane CAT 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, 3/4, NPT Entry |

| SPXCDUSNRX | UL/cUL approved Methane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, 3/4, NPT Entry |

| SPXCDUSNPX | UL/cUL approved Propane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, 3/4, NPT Entry |

| SPXCDUSNO1 | UL/cUL approved Oxygen 25.0% v/v with 316SS, 3/4, NPT Entry |

| SPXCDUSNHX | UL/cUL approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with 316SS, 3/4, NPT Entry |

| SPXCDUSNCX | UL/cUL approved Carbon Monoxide 0-300ppm (100 to 1000ppm, 100ppm) with 316SS, 3/4, NPT Entry |

| SPXCDUSNG1 | UL/cUL approved Hydrogen 0-1000ppm with 316SS, 3/4, NPT Entry |

| SPXCDUSNNX | UL approved SP XCD Nitrogen Dioxide 0-50ppm with SS316, 3/4, NPT Entry |

| SPXCDUSNB1 | UL/cUL approved Carbon Dioxide IR 0-2.00% v/v with 316SS, 3/4, NPT Entry |

| SPXCDUSNB2 | UL/cUL approved Carbon Dioxide IR 0-5.00% v/v with 316SS, 3/4, NPT Entry |

| Sensepoint XCD transmitter and sensor KIT (ATEX/IECEx/AP*, LM25 and M20 Entry with Modbus) | |

| SPXCDALMFXM | ATEX/IECEx/AP* Methane CAT 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry, with Modbus |

| SPXCDALMRXM | ATEX/IECEx/AP* Methane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry, with Modbus |

| SPXCDALMPXM | ATEX/IECEx/AP* Propane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, M20 Entry, with Modbus |

| SPXCDALMO1M | ATEX/IECEx/AP* Oxygen 25.0% v/v with LM25, M20 Entry, with Modbus |

| SPXCDALMHXM | ATEX/IECEx/AP* Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with LM25, M20 Entry, with Modbus |

| SPXCDALMCXM | ATEX/IECEx/AP* Carbon Monoxide 0-500ppm (100 to 1000ppm, 100ppm) with LM25, M20 Entry, with Modbus |

| SPXCDALMG1M | ATEX/IECEx/AP* Hydrogen 0-1000ppm with LM25, M20 Entry, with Modbus |

| SPXCDALNNXM | ATEX/IECEX /AP approved Nitrogen Dioxide 0-50ppm with LM25, M20 Entry, With Modbus |

| SPXCDALMB1M | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-2.00% v/v with LM25, M20 Entry, with Modbus |

| SPXCDALMB2M | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-5.00% v/v with LM25, M20 Entry, with Modbus |

| Sensepoint XCD transmitter and sensor KIT (ATEX/IECEx/AP*, 316SS and M20 Entry with Modbus) | |

| SPXCDASMFXM | ATEX/IECEx/AP* approved Methane CAT 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry, with Modbus |

| SPXCDASMRXM | ATEX/IECEx/AP* approved Methane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry, with Modbus |

| SPXCDASMPXM | ATEX/IECEx/AP* approved Propane IR 0-100%LEL (20 to 100%LEL, 10%LEL) with 316SS, M20 Entry, with Modbus |

| SPXCDASMO1M | ATEX/IECEx/AP* approved Oxygen 25.0% v/v with 316SS, M20 Entry, with Modbus |

| SPXCDASMHXM | ATEX/IECEx/AP* approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with 316SS, M20 Entry, with Modbus |

| SPXCDASMCXM | ATEX/IECEx/AP* approved Carbon Monoxide 0-300ppm (100 to 1000ppm, 100ppm) with 316SS, M20 Entry, with Modbus |

| SPXCDASMG1M | ATEX/IECEx/AP* approved Hydrogen 0-1000ppm with 316SS, M20 Entry, with Modbus |

| SPXCDASNNXM | ATEX/IECEX /AP approved Nitrogen Dioxide 0-50ppm with SS316, M20 Entry, With Modbus |

| SPXCDASMB1M | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-2.00% v/v with 316SS, M20 Entry, with Modbus |

| SPXCDASMB2M | ATEX/IECEx/AP* approved Carbon Dioxide IR 0-5.00% v/v with 316SS, M20 Entry, with Modbus |

| UL APPROVAL (Epoxy Coated Aluminum Alloy, LM25, With Modbus) | |

| SPXCDULNFXM | UL/cUL approved Flammable CAT 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNRXM | UL/cUL approved Methane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNPXM | UL/cUL approved Propane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNO1M | UL/cUL approved Oxygen 25.0% v/v with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNHXM | UL/cUL approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNCXM | UL/cUL approved Carbon Monoxide 0-500ppm (100 to 1000ppm, 100ppm) with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNG1M | UL/cUL approved Hydrogen 0-1000ppm with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNNXM | UL/cUL approved Nitrogen Dioxide 0-50ppm with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNB1M | UL/cUL approved Carbon Dioxide IR 0-2% v/v with LM25, 3/4, NPT Entry, with Modbus |

| SPXCDULNB2M | UL/cUL approved Carbon Dioxide IR 0-5% v/v with LM25, 3/4, NPT Entry, with Modbus |

| UL APPROVAL (Epoxy Coated Stainless Steel, SS316, With Modbus) | |

| SPXCDUSNFXM | UL/cUL approved Flammable CAT 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNRXM | UL/cUL approved Methane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNPXM | UL/cUL approved Propane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNO1M | UL/cUL approved Oxygen 25.0% v/v with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNHXM | UL/cUL approved Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNCXM | UL/cUL approved Carbon Monoxide 0-500ppm (100 to 1000ppm, 100ppm) with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNG1M | UL/cUL approved Hydrogen 0-1000ppm with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNNXM | UL/cUL approved Nitrogen Dioxide 0-50ppm with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNB1M | UL/cUL approved Carbon Dioxide IR 0-2% v/v with SS316, 3/4, NPT Entry, with Modbus |

| SPXCDUSNB2M | UL/cUL approved Carbon Dioxide IR 0-5% v/v with SS316, 3/4, NPT Entry, with Modbus |

| Replacement sensor Cartridge | |

| SPXCDXSFXSS | Methane CAT 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) |

| SPXCDXSRXSS | Methane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) |

| SPXCDXSPXSS | Propane IR 0-100%LEL (20,0 to 100.0%LEL, 10%LEL) |

| SPXCDXSO1SS | Oxygen 25.0% v/v only |

| SPXCDXSHXSS | Hydrogen Sulfide 0-50ppm (10.0 to 100.0ppm, 1ppm) |

| SPXCDXSCXSS | Carbon Monoxide 0-500ppm (100 to 1000ppm, 100ppm) |

| SPXCDXSG1SS | Hydrogen 0-1000ppm only |

| SPXCDXSNXSS | Nitrogen Dioxide 0-10ppm (10.0 to 50.0ppm) |

| SPXCDXSB1SS | Carbon Dioxide IR 0-2.00% v/v only |

| SPXCDXSB2SS | Carbon Dioxide IR 0-5.00% v/v only |

| Accessories | |

| S3KCAL | Calibration cap |

| SPXCDCC | Collecting cone for use with lighter than air gases |

| SPXCDDMK | Duct mounting kit |

| SPXCDMTBR | Pipe Mounting bracket (including fixings and hex wrench set) |

| SPXCDSDP | Sunshade / Deluge Protection |

| SPXCDHMANEN | Hard Copy Manual in English language |

| SPXCDHMANCN | Hard Copy Manual in Chinese language |

| SPXCDHMANKR | Hard Copy Manual in Korean language |

| Spares | |

| SPXCDDMT12 | Replacement display module (O2 & Toxic) |

| SPXCDDMF12 | Replacement display module (FL & IR) |

| SPXCDTMO12 | Replacement terminal module (O2) |

| SPXCDTMT12 | Replacement terminal module (Toxic) |

| SPXCDTMF12 | Replacement terminal module (FL & IR) |

| SPXCDMBUS | Replacement Modbus Module |

| SPXCDSERVK | Service Kit containing all o-rings, terminal module and locking screws |

| SPXCDTOOLK | Factory toolkit containing magnetic wand and hex wrenches for locking and earth screws |

| SPXCDTMK | Terminal block set |

| SPXCDNPTP | 3/4, NPT Plug |

| SPXCDM20P | M20 Plug |

| SPXCDMANCD | Instruction manual CD-ROM |

| SPXCDNADP | 3/4, NPT to M20 Adaptor |

| SPXCDWP | Weather Protection |

| SPXCDSRLS | Sensor Retainer with locking screw |

| SPXCDEBS | Earth Bracket and Screws |

| Special Flammable Gas Calibration | |

| SPXCDSFGC1 | Special Flammable Gas Calibration, 0-100%LEL, 1* |

| SPXCDSFGC2 | Special Flammable Gas Calibration, 0-100%LEL, 2* |

| SPXCDSFGC3 | Special Flammable Gas Calibration, 0-100%LEL, 3* |

| SPXCDSFGC4 | Special Flammable Gas Calibration, 0-100%LEL, 4* |

| SPXCDSFGC5 | Special Flammable Gas Calibration, 0-100%LEL, 5* |

| SPXCDSFGC7 | Special Flammable Gas Calibration, 0-100%LEL, 7* |

| SPXCDSFGC8 | Special Flammable Gas Calibration, 0-100%LEL, 8* |

Note: If no Special Flammable Gas Calibration part no. is included on PO, a Methane (6* calibration will be supplied)

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.