how to chose Ultrasonic Sensor

Due to their ruggedness and low cost, ultrasonic sensors are widely used in various consumer and industrial areas as an advanced and well-known technology. When adding a measuring distance or detection function to a product, an ultrasonic sensor is the ideal option. Furthermore, it has a broader applicability and improved dependability in hardware upgrades and software adaptations.

Ⅰ What is an Ultrasonic Sensor?

An ultrasonic sensor is a type of electronic equipment that emits ultrasonic sound waves and converts the reflected sound into an electrical signal to determine the distance of a target item. Ultrasonic waves travel quicker than audible sound (i.e. the sound that humans can hear). The transmitter, which generates sound using piezoelectric crystals and the receiver, which encounters the sound after it has traveled to and from the target, are the two primary components of ultrasonic sensors.

Ultrasonic sensors are mostly utilized as proximity sensors. They can be found in self-parking technology and anti-collision safety systems in automobiles. In addition to robotic obstacle detection systems, ultrasonic sensors are used in manufacturing technology. Ultrasonic sensors are less susceptible to interference from smoke, gas, and other airborne particles than infrared (IR) sensors in proximity detection applications (though the physical components are still affected by variables such as heat).

Ultrasonic sensors are also utilized as level sensors in closed containers to detect, monitor, and manage liquid levels such as vats in chemical factories.Most notably, ultrasonic technology has allowed the medical profession to create images of interior organs, spot malignancies, and monitor the health of newborns in the womb.

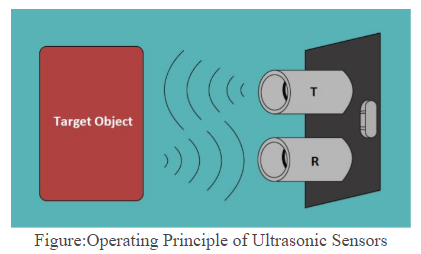

Ⅱ Operating Principle of Ultrasonic Sensors

Ultrasonic sensors operate by emitting a sound wave at a frequency that is above the range of human hearing. To receive and transmit ultrasonic sound, the sensor's transducer functions as a microphone. Like many others, our ultrasonic sensors use a single transducer to send a pulse and receive the echo. The sensor calculates the distance to a target by measuring the time elapsed between delivering and receiving the ultrasonic pulse. This module's operation is straightforward. It emits a 40kHz ultrasonic pulse that travels through the air and, if it encounters an obstruction or object, bounces back to the sensor.The distance can be estimated by multiplying the travel time by the speed of sound.

Ultrasonic sensors are an excellent solution for detecting clear objects. Because of target translucence, applications that use infrared sensors, for example, struggle with this particular use case for liquid level measurement.

Ultrasonic sensors detect things independent of color, surface, or material for presence detection (unless the material is very soft like wool, as it would absorb sound.)

Ultrasonic sensors are a trustworthy solution for detecting translucent and other things where optical methods may fail.

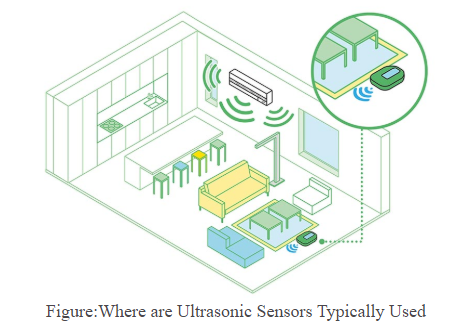

Ⅲ Where are Ultrasonic Sensors Typically Used?

Liquid level sensing is the first of the two most frequent ultrasonic sensor applications, as they can detect liquids of any hue or opacity while remaining non-contact. The second is universal object detection, which is advantageous because of its low cost and simplicity. Anti-collision detection for vehicles, person identification, presence detection, box sorting, pallet detection with forklifts, bottle counting on drink filling machines, and many other applications are examples of object detection applications.

Ⅳ Advantages and Disadvantages of Ultrasonic Sensors

4.1 Advantages of Ultrasonic Sensors

1.Not affected by the color or transparency of the object

Because the ultrasonic sensor reflects the sound out of the item, the color or transparency of the object does not affect the sensor's reading.

2.Can it be used in low-light conditions?

Dark settings have little effect on the detecting capability of ultrasonic sensors, unlike proximity sensors that use light or cameras.

3.Unaffected by dust, filth, or high humidity levels

Although many sensors perform well in these situations, others generate inaccurate readings, particularly in extreme conditions when substantial volumes of dust or water build.

4.High precision in some applications

When measuring the thickness and distance between parallel surfaces, ultrasonic sensors have a high degree of precision.

5.Penetration

The ultrasonic sensor's high sensitivity and penetrating capability make it easier to detect the outside environment as well as deep things.

6.Strong anti-environmental interference:

It is very resistant to environmental influence and may be used in any lighting environment. Reliable performance in a wide range of illumination settings, including indoor, outdoor, and complicated ambient light. Because ultrasonic sensors are not affected by smoke or black matter and can detect light, smoke, dust, colors, materials, and so on, they are superior to infrared sensors in various applications.

7.Wide range of applications:

Ultrasonic sensors may be utilized for a variety of applications such as water level detection, drone applications, automatic obstacle avoidance applications, distance detection applications, and so on.

8.Multi-purpose:

Detection of presence or absence, detection of level, detection of location, detection of distance, and so on. It can suit the needs of the majority of non-contact detecting applications

4.2 Disadvantages of Ultrasonic Sensors

• Unable to work in a vacuum.

Because ultrasonic sensors rely on sound to function, they simply cannot function in a vacuum because there is no air to disperse the sound.

• Unsuitable for use underwater

• Soft materials will have an impact on sensing accuracy. Objects wrapped in a soft fabric absorb more sound waves, making it difficult for the sensor to see the target.

• A temperature change of 5-10 degrees Celsius or higher will influence sensor accuracy.

However, many manufacturers' devices now include temperature correction, and these sensors can be calibrated at starting or before each range reading based on any changes in temperature, voltage, and so on.

• Small objects have a tough time reflecting sound waves.The object may be too small to reflect enough sound waves to the sensor to be detected.

• It is difficult to capture the reflected wave in some shapes.

Ⅴ Limitation of Ultrasonic Sensors

Ultrasonic sensors, such as the HC-SR04, can measure distances of up to 400 cm with a 3 mm tolerance. However, if a target object is placed in such a way that the ultrasonic signal is deflected away rather than reflected by the ultrasonic sensor, the measured distance may be wrong. In some circumstances, the target object is so small that the reflected ultrasonic signal is insufficient to identify it and the distance cannot be accurately determined.

Moreover, things such as fabric and carpet can absorb auditory impulses. If the signal is absorbed at the end of the target item, it cannot be reflected the sensor, and so the distance cannot be recorded.

The high sensitivity of ultrasonic sensors makes them efficient, but it can also present issues. Ultrasonic sensors, for example, can identify spurious signals from airwaves disrupted by an air conditioning system and a pulse from a ceiling fan.

Ultrasonic sensors can detect items within their range, but they can't tell the difference between different forms and sizes. However, by employing two sensors instead of simply one, this constraint can be circumvented. Both sensors can be installed at a distance from each other or next to each other. The shape and size of the target item can be determined by examining the overlapped shaded zone.

Ⅵ FAQs about Ultrasonic Sensors

How many types of ultrasonic sensors are there?

Four types.All together there are four types of ultrasonic sensors, classified by frequency and shape: the drip-proof type, high-frequency type, and open structure type (lead type and SMD type).

Which ultrasonic sensor is best?

First,5Pcs Ultrasonic Sensor Module Kit HC-SR04 Distance Sensor with 3pcs Mounting Bracket Compatible with Arduino UNO Mega R3 Mega2560 Duemilanove Nano Rapsberry Pi 3 Robot XBee ZigBee. Sencond,waterproof Ultrasonic Module JSN-SR04T Water Proof Integrated Distance Measuring Transducer Sensor for Arduino.

How can we protect ultrasonic sensor from water?

Speaker grill cloth, wire mesh, and an open-celled foam are ways to conceal ultrasonic sensors for your application.For proper operation, moisture, temperature, and acoustic return must be taken into consideration when attempting to conceal the sensor.

Do ultrasonic sensors interfere with each other?

A basic ultrasonic sensor will have interference in the reported range when more than one sensor is operating in the same general space.Since the sensors are not synchronized, the sensors will range at slightly different intervals. These frequency drifts cause interference between sensors for most applications.

How accurate are ultrasonic sensors?

The more accurate ultrasonic sensors can achieve 0.1-0.2% of the detected range under perfectly controlled conditions, and most good ultrasonic sensors can generally achieve between 1% and 3% accuracy.

How far can ultrasonic sensor work?

Ultrasonic sensors are suitable for close range detection up to ten meters and provide multiple range measurements per second.

What is the principle of an ultrasonic sensor?

Outline and detection principle. As the name indicates, ultrasonic sensors measure distance by using ultrasonic waves. The sensor head emits an ultrasonic wave and receives the wave reflected back from the target. Ultrasonic Sensors measure the distance to the target by measuring the time between the emission and reception.

What is the range of ultrasonic sensors?

Ultrasonic sensors are suitable for close range detection up to ten meters and provide multiple range measurements per second.

What are the advantages of ultrasonic smoke detectors?

Ultrasonic sensors are suitable for close range detection up to ten meters and provide multiple range measurements per second. Low power consumption – can be powered by battery, inexpensively. It can operate in many environmental conditions – ultrasonic sensors work in smoke-filled environments, where other sensors would fail.

What is ultrasonic sensor in IoT?

IoT ultrasonic sensors are designed for non-contact detection of solid and liquid objects. These sensors are used for a wide variety of functions from monitoring the level of water in a tank to fluid identification/concentration, to detecting object proximity.