Wall-side control of omnidirectional mobile platform based on ultrasonic sensor

Aiming at the autonomous navigation along the wall, an omnidirectional moving platform composed of omnidirectional wheel, stepper motor, ultrasonic sensor and 52 single chip microcomputer was built, and its motion characteristics were analyzed. The hardware design of the autonomous wall-side navigation system for omnidirectional mobile platform is carried out, and a wall-side control strategy is proposed, which combines full motion and differential motion. The experimental results show that the control strategy can effectively realize the autonomous and accurate wall-side navigation, and provides a method for the wall-side navigation control of omnidirectional mobile platform.

0 Preface

Navigation along the wall means that the robot walks along the outline of the wall and maintains a certain distance from the wall without collision [1]. Navigation along the wall has been applied in many fields, such as indoor cleaning robot, elderly service robot, AGV car, fire extinguishing robot and so on.

Walking along the wall is one of the ways for the robot to navigate autonomously with the help of the environment. The key lies in how to acquire the environmental knowledge, which needs the help of the external sensor of the robot. Sensors such as vision, infrared, laser and ultrasonic have all been applied in mobile robots [2]. However, ultrasonic sensors have been widely used in mobile robot sensing systems due to their advantages such as high cost performance and simple hardware implementation [3].

Guo Xiaoqin et al. [1, 3-4] did a wall-walking study on ordinary differential wheel robots, and achieved a good wall-walking effect of proximity through experiments. However, for ordinary wheeled mobile mechanisms, turning requires a certain rotation radius, which often loses its effect in a narrow space due to the inability to move horizontally, which limits the use of wheeled robots to a certain extent [5]. Omnidirectional mobile mechanism is especially suitable for small moving space, frequent turning, short walking distance or lateral movement.

In this paper, the author proposes a wall-navigation control system and control strategy for omnidirectional mobile platform based on ultrasonic sensor distance measurement.

1 Omnidirectional mobile platform chassis design

The omnidirectional mobile platform chassis adopts an omnidirectional mobile mechanism. As shown in Figure 1, four omnidirectional wheels are sympathetically distributed on the bottom plate. The four omnidirectional wheels are connected by coupling and four stepper motors respectively. The axes of the four stepper motors intersect at one point and are perpendicular to each other, forming a 90° staggered Angle.

Since the circumference of the omnidirectional wheel is composed of a number of small rolls, the axis of the roller is tangent to the circumference of the wheel, and can rotate freely, such a structure makes the omnidirectional wheel have three degrees of freedom: rotation around the wheel axis, rotation of the roller axis and the vertical direction of the roller axis (that is, compared with the ordinary wheel has a side slide function).

2 Motion mode of omnidirectional mobile platform

The working space of the omnidirectional moving platform is a plane. As shown in Figure 2 (a), a plane rectangular coordinate system is established with the axes of the four wheels as x and y axes respectively and the intersection point of the axes of the four wheels, that is, the geometric center of the omnidirectional moving platform, as the origin.

3 Hardware design of autonomous wall-navigation system for omnidirectional mobile platform

3.1 Overall system structure

As shown in Figure 3, the system is mainly composed of STC89C52 MCU, 2 ultrasonic circuits and 4 motor drive circuits. The system uses STC89C52 single chip microcomputer with low power consumption, strong anti-interference and high performance as the main controller of the system, receives the distance signal between the obstacle measured by two ultrasonic sensors, sends instructions to the motor drive circuit through the autonomous wall-navigation algorithm, and drives the omnidirectional mobile platform to autonomously navigate along the wall.

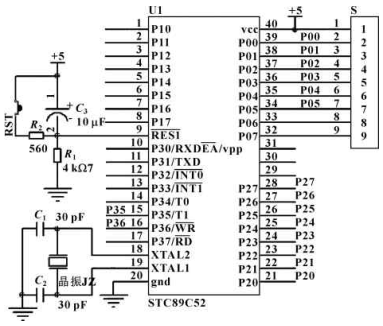

3.2 Control System

As shown in Figure 4, the control system is mainly composed of STC89C52 MCU, clock circuit and reset circuit. STC89C52 MCU has the characteristics of strong anti-interference performance, fast speed, low power consumption and full compatibility of instruction code with 8051 MCU [6]. The clock circuit adopts the internal clock mode, which is realized by connecting the XTAL1 and XTAL2 pins of STC89C52 microcontroller with quartz crystal and two fine tuning capacitors. The reset circuit adopts the mode of power-on automatic reset and key reset.

3.3 Ultrasonic ranging circuit

The ultrasonic ranging circuit is used to measure the distance to obstacles. General ultrasonic module effective distance is less than 5 m [7], KSl03 ultrasonic sensor with temperature compensation function, high measurement accuracy, the use of temperature correction distance command, direct output distance (unit is mm), the highest accuracy in short distance up to 1 mm; The measurement blind area is as small as 1 cm, and the maximum range can reach 11 m, basically no blind area; Use I2C interface to communicate with the host, automatically respond to the host's I2C control command; Power saving mode: With automatic sleep function, the module automatically enters the rest state within 5 s without receiving the host instruction, and is awakened by the host I2C control command [8]. KSl03 supports temperature correction distance detection and temperature detection, the measurement distance is large, in I2C mode, an I2C bus or a pair of IO port can be connected to 20 KS103, so KSl03 ultrasonic ranging is used.

The connection pins on the KS103 ranging module are identified as: VCC, SDA/TX (referred to as SDA), SCL/RX (referred to as SCL), GND, MODE. When the MODE pin is suspended, KS103 works in I2C mode, where VCC is used to connect + 5V (3 0 ~ 5 5V range is available) power supply, GND is used to connect power supply, SDA/TX is the data line for I2C communication. The SCL/RX pin is the clock line for I2C communication. The SCL and SDA cables need to connect a 4 7 kΩ (resistance value 1 to 10 kΩ) resistor from the host to the VCC. The P35 and P36 pins of the microcontroller are respectively connected to the SCL and SDA pins of the KS103 ranging module as the clock line SCL and data line SDA of I2C communication. The interface circuit is shown in Figure 5.

Figure 5 Ultrasonic sensor and MCU interface circuit

KS103 ranging module data includes distance, round-trip time and temperature, the MCU through the I2C bus to KS103 module register 0x02 write 8-bit detection instruction 0xbc (the instruction detection distance is 0 ~ 11 m, with temperature compensation), wait for the conversion time to, Read the 16-bit distance measurement value [9] in the 0x02 and 0x03 registers of the KS103 module in mm.

3.4 Stepper motor drive circuit

The stepper motor adopts two-phase four-wire hybrid high-torque 42 series stepper motors with working voltage of 12 ~ 24 V, rated phase current of 1.65 A, step Angle of 1 8° and torque of 0 55 N· m. A4988 is A complete micro-step motor driver, which can drive two-phase stepper motors in full, half, 1/4, 1/8 and 1/16 stepping modes. The output drive performance can reach 35 V and ±2 A. Sufficient driving power is provided for the stepper motor of the system [10]. With a built-in converter, the A4988 is easy to operate and only needs to input a pulse into the stepper port to drive the motor to generate microsteps without the need for phase sequence tables, high-frequency control lines or complex interfaces [11].

A4988 stepper motor driver chip main ports are ENABLE, DIR, STEP, MS1, MS2, MS3. The ENABLE port can be controlled by a single chip microcomputer port or directly connected to GND. EN⁃ABLE port input high voltage, motor does not rotate, input low voltage, motor rotation. Input a pulse in the STEP pin to drive the stepper motor to generate microsteps. Set the pulse frequency to control the stepper motor rotation speed. MS1, MS2 and MS3 connect high and low levels respectively to set the stepping mode according to Table 1, so as to select different step angles and excitation modes [10]. DIR port input high level, the stepper motor rotates clockwise, input low level, the stepper motor rotates counterclockwise. The connection circuit of A4988 motor drive core chip and single chip machine is shown in Figure 6.

The P00-P05 port of the single chip is connected to the input ports 1 ~ 6 of the four stepper motor driver chip A4988 at the same time to control the enabling, stepping Angle and incentive mode of the stepper motor. The P2 port of the microcontroller is connected with the STEP and DIR ports of A4988 respectively to control the speed and direction of the stepper motor. The output terminals 1A and 1B of the four stepper motor drive chips A4988 are respectively connected to the two ends of the stepper motor in phase, and the output terminals 2A and 2B are respectively connected to the two ends of the other phase of the stepper motor.

4. Navigation control strategy along the wall

The walking direction of the omnidirectional moving platform is parallel to the wall, and the center of the omnidirectional moving platform always maintains a certain distance from the wall. Two ultrasonic sensors are installed parallel to the side perpendicular to the walking direction near the wall, and the distance of the ultrasonic sensor from the center line of the omnidirectional moving platform is 100 mm. The omnidirectional mobile platform uses a differential walking mode when it walks in a straight line, that is, No. 1 and No. 3 wheels do not turn, No. 2 wheels reverse, No. 4 wheels turn, and No. 2 and No. 4 wheels have the same speed. Since the No. 1 and No. 3 wheels are respectively driven by a two-step motor, coupled with the inconsistent friction between the wheels and the ground, it is difficult to fully synchronize the two wheels even under the same drive signal, and the difference is greater with the change of time, and the intuitive appearance is that they will deviate from the expected route. The control strategy of walking along the wall is to control the omnidirectional mobile platform to always walk parallel to the wall and keep a certain distance.

In order to intuitively clarify the control strategy of walking along the wall, a linear wall can be taken as an example. As shown in Figure 7, the expected omnidirectional moving platform can walk along a linear wall 400 mm away from the wall (the distance value is adjustable). According to the position of the center line of the omnidirectional mobile platform and the expected linear path, five cases can be divided. In the first type of case, as shown in FIG. 7 (a), the center line of the omnidirectional mobile platform completely coincides with the expected linear path, and the distance of the ultrasonic sensor 1 = the distance of the ultrasonic sensor 2 = the set distance, then there is no need to adjust and the omnidirectional mobile platform moves forward in a straight line. In the second category, as shown in FIG. 7 (b), the center line of the moving platform deviates to the left and intersects with the expected linear path. If the distance of ultrasonic sensor 1 is < set distance, and the distance of ultrasonic sensor 2 > set distance, the omnidirectional moving platform is controlled to turn right. In the third case, as shown in Figure 7 (c), when the center line of the moving platform deviates to the right and intersects with the expected linear path, the distance of ultrasonic sensor 1 is > set distance, and the distance of ultrasonic sensor 2 is < set distance, then the omnidirectional moving platform is controlled to the left. In the fourth case, as shown in Figure 7 (d), the center line of the moving platform deviates to the left and is parallel to the expected linear path, and the distance of ultrasonic sensor 1 = the distance of ultrasonic sensor 2 < set distance, then the right movement of the omnidirectional moving platform is controlled. In the fifth case, as shown in Figure 7 (e), the center line of the moving platform deviates to the right and is parallel to the expected linear path, and the distance of ultrasonic sensor 1 = distance of ultrasonic sensor 2 > set distance, then the left movement of the omnidirectional moving platform is controlled. For the first type of linear forward situation, the differential walking mode is used, the 1 and 3 wheels do not turn, and the 2 and 4 wheels turn, which not only saves energy consumption but also walks a straight line compared to the full-motion linear walking mode. For the second type of right turn and the third type of left turn, the full motion mode is used to give full play to the advantages of the full motion mode, right turn and left turn can be rotated around the geometric center of the omnidirectional moving platform, and the turning radius is small; For the fourth type of right shift and the fifth type of left shift, the differential mode is also used, and the No. 2 and No. 4 wheels do not turn, and the No. 1 and No. 3 wheels turn, which can make the omnidirectional mobile platform move directly to the expected path and adjust quickly.

5 Experimental Results

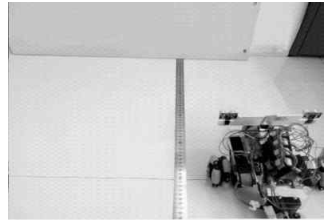

During the experiment, in order to visually see the walking track of the omnidirectional mobile platform, white paper was laid on the floor, the omnidirectional mobile platform was placed on the white paper, and a general purpose signature pen was installed in the center of the omnidirectional mobile platform. In this way, in the process of walking on the omnidirectional mobile platform, the signature stroke trace will be left, which is the movement trajectory of the omnidirectional mobile platform.

When the omnidirectional moving platform walks along the straight wall, the value set for the ultrasonic sensors 1 and 2 is 400 mm, which can be seen from the trace of the signature stroke that the track is parallel to the wall. Theoretically, the distance of the track should be the value set by the ultrasonic sensor of 400 mm+ the distance between the ultrasonic sensor and the center of the omnidirectional moving platform of 100 mm (as shown in Figure 8) = 500 mm. In fact, it can be read from the ruler in the figure that the distance is 502 mm, the error is 2 mm, and the error is small. It shows that the omnidirectional mobile platform can walk along the linear wall more accurately.

The omnidirectional moving platform walks along a straight wall and a curved wall. It can be seen from the marks of signature strokes that the track of the omnidirectional moving platform starts with a left-moving line segment 1, a straight-forward line segment 2 and a curved line segment 3, and the movement track is smooth. The initial position of the omnidirectional moving platform placed on the paper is randomly placed, and the initial bit of the omnidirectional moving platform is far away from the wall, so the omnidirectional moving platform moves left under the program control and quickly reaches the distance between its center and the wall of 500 mm, thus forming a movement track of the left shift line segment 1. Then the omnidirectional moving platform keeps a distance of 500 mm from the wall and walks along the straight wall, forming the motion track of the straight forward line segment 2. Finally, the omnidirectional moving platform keeps a distance of 500 mm from the wall and walks along the arc wall, forming the motion track of arc line segment 3. Of course, changing the value set by the ultrasonic sensor (greater than the minimum blind area of 1 cm, less than the maximum range of 11 m), that is, changing the distance between the center of the omnidirectional mobile platform and the wall, the omnidirectional mobile platform can also realize walking along the wall.

FIG. 8 Experiment of omnidirectional moving platform walking along a straight wall

6 Conclusion

The omnidirectional mobile platform, which is composed of omnidirectional wheel and stepper motor, uses 52 single chip microcomputer as controller, ultrasonic sensor to realize distance measurement, and adopts the navigation strategy of differential plus full motion to control the omnidirectional mobile platform along the wall. The experimental results show that the omnidirectional moving platform can maintain a certain distance along the wall and accurately navigate along the wall. The proposed navigation strategy of the omnidirectional moving platform along the wall based on ultrasonic wave is effective, and provides an effective method for the omnidirectional moving platform's navigation control along the wall.

References:

[1] Guo Xiaoqin, Chen Zhuqi. Navigation control of Mobile Robot along wall based on infrared PSD [J]. Machine Tool & Hydraulics, 2009,37 (9) : 133-136.

[2] Ding Zhensheng. Sensors and sensing technology applications [M]. Beijing: Publishing House of Electronics Industry, 1999.

[3] Jin Wenjun, Feng Hao, Hua Liang. Detection system of autonomous mobile Robot based on ultrasonic sensor [J]. Modern Electronic Technology, 2008,31 (4) : 156-158.

[4] Fu Zhikai, Xing Jianchun. Research on Mobile Robot Navigation along wall Based on Compound Control Algorithm [J]. Computer Application and Software, 2012,29 (9) : 234-236.

[5] Shi Weiliang. Design of motion control system for omnidirectional mobile robot [D]. Nanjing: Southeast University, 2008.

[6] Zhou Peng. Design of Electronic Compass-Ultrasonic Obstacle Detection System based on STC single chip computer [J]. Electronic Design Engineering, 2013,21 (10) : 163-166.

[7] Wang Zhichao, Liu Bo, Zhang Leran. Design of new intelligent lighting controller based on sensor network [J]. Computer Measurement and Control, 2014,22 (3) : 716-718.

[8] Chen Peixing, Zhang Xiaofei, Yang Juan. Design of ultrasonic speech ranging crutch based on SYN6288 [J]. Shanxi Electronic Technology, 2015 (1) : 11-12.

[9] Liu Hui. Research on height measurement method of small UAV based on ultrasonic ranging technology [D]. Hohhot: Inner Mongolia University of Technology, 2015.

[10] Tan Xiuteng, Guo Xiaoding, Bruce Lee, et al. Design of desktop 3D printer control system based on ARM [J]. Applied Science and Technology, 2014 (5) : 57-61.

[11] Xie Tong, Zhang Miya, Yao Jianfei. Design of Control System of 3D Printing Rapid Molding Machine for Automobile Injection Parts [J]. Journal of Zhejiang Vocational and Technical College of Communications, 2016, 17 (2) : 49-53.