Honeywell Kromschroder

Product Description

APPLICATION

The Q7130, Q7230, and Q7330 Modutrol IV Interface Modules are used with Series 90 Modutrol IV Motors (M91XX) for conversion to electronic (Series 70) control.

FEATURES• Mounts inside the wiring box of any Series 90 Modutrol IV Motor (M91XX models). Module protected from weather by the Modutrol IV NEMA 3 wiring box.• Mates to quick-connect terminals in motor wiring box and provides screw terminals for control wiring connections. • Features solid state circuitry with surface mount components.• Plastic enclosure provides easy handling and protection for circuitry.• Q7130A provides selectable voltage range (4-7, 6-9, or 10.5-13.5 Vdc). Adapts M91XX Modtrol IV Motor to function as M71XX model for M734H,J, M744D, M745G,P replacements. Includes reversing switch to allow replacement of electrically normally open or electrically normally closed motors.• Q7230A provides current or voltage control (4-20 mA and 2-10 Vdc) with adjustable zero and span. Adapts the M91XX Modutrol IV Motor to function as M72XX model for M744S,T,Y or M745S,T,Y replacements. Includes reversing switch to allow replacement of electrically normally open or electrically normally closed motors.• Q7330A is an interface to W936 and W945 controls. Adapts the M91XX Modutrol IV Motor to function as M73XX model for M734D, M744A, M745A replacements.

Table 1 SPECIFICATIONSIMPORTANTThe specifications given in this publication do not include normal manufacturing tolerances. Therefore, this unit may not exactly match the listed specifications. Also, this product is tested and calibrated under closely controlled conditions and some minor differences in performance can be expected if those conditions are changed.

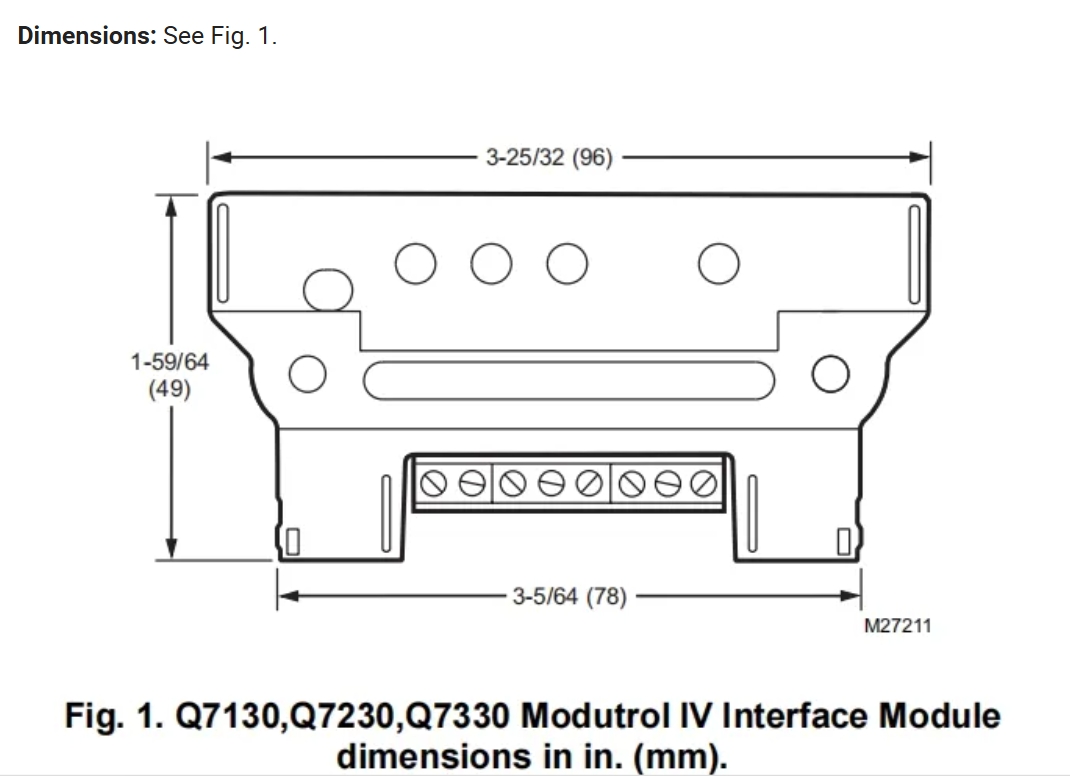

Models:Q7130A Modutrol IV Interface Module:Used with M91XX Modutrol IV Motor to replace M71XX Motor applications. Module controls only one motor. See Table 1. Q7230A Modutrol IV Interface Module:Used with M91XX Modutrol IV Motor to replace M72XX Motor applications. Module controls only one motor. See Table 1. Q7330A Modutrol IV Interface Module:Used with M91XX Modutrol IV Motor to replace M73XX Motor applications. Module controls only one motor. See Table 1.Input Impedance: Q7130A: >100k ohms. Q7230A: voltage input >100k ohms; current input 67 ohms.Temperature Rating: -40° F to +150° F [-40° C to + 66° C].Dimensions: See Fig. 1.

Table 1. Interface Module Function/Application Chart.

| This Model | Provides Interface For | And ReplacesThese Old StyleMotorsa | When Used withSeries 90 Models: | ||||||||||

| Q7130A | Selectable voltage ranges: 4-7, 6-9, or 10.5 to 13.5 Vdc | M734H | M9164D1009 | ||||||||||

| M734J | |||||||||||||

| M744Db | M9184D1021 | ||||||||||||

| M745G | M9185A1018 | ||||||||||||

| Q7230A | Adjustable zero and span, voltage or current M9184D1021control (includes 4-20 mA and 2-10 Vdc). | M744S | M9184D1021 | ||||||||||

| M744T | |||||||||||||

| M744Y | |||||||||||||

| M745S | M9185D1004 | ||||||||||||

| M745T | |||||||||||||

| M745Y | |||||||||||||

| Q7330A | W936 or W945 control interface. | M734D | M9164D1009 | ||||||||||

| M744A | M9184D1021 | ||||||||||||

| M745A | M9185D1004 | ||||||||||||

INSTALLATIONWhen Installing This Product…

1. Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.2. Check the ratings and description given in this specification to make sure the product is suitable for your application.3. Installer must be a trained, experienced service technician.4. After installation is complete, check out product operation as provided in these instructions.

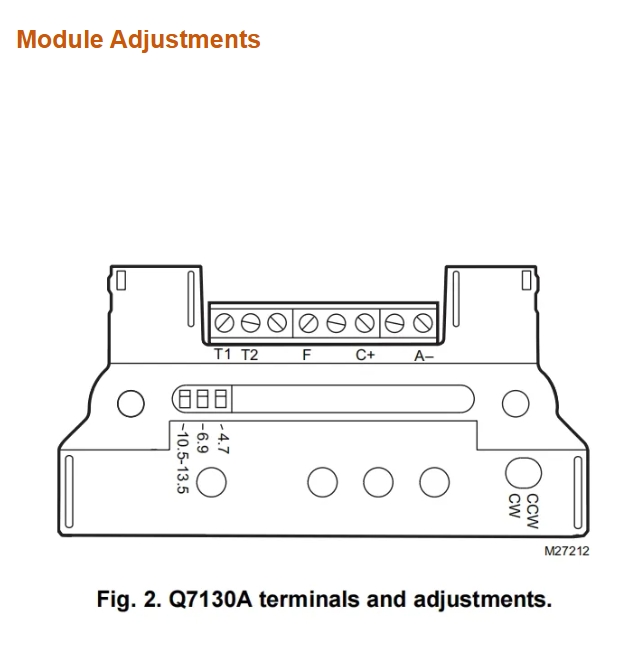

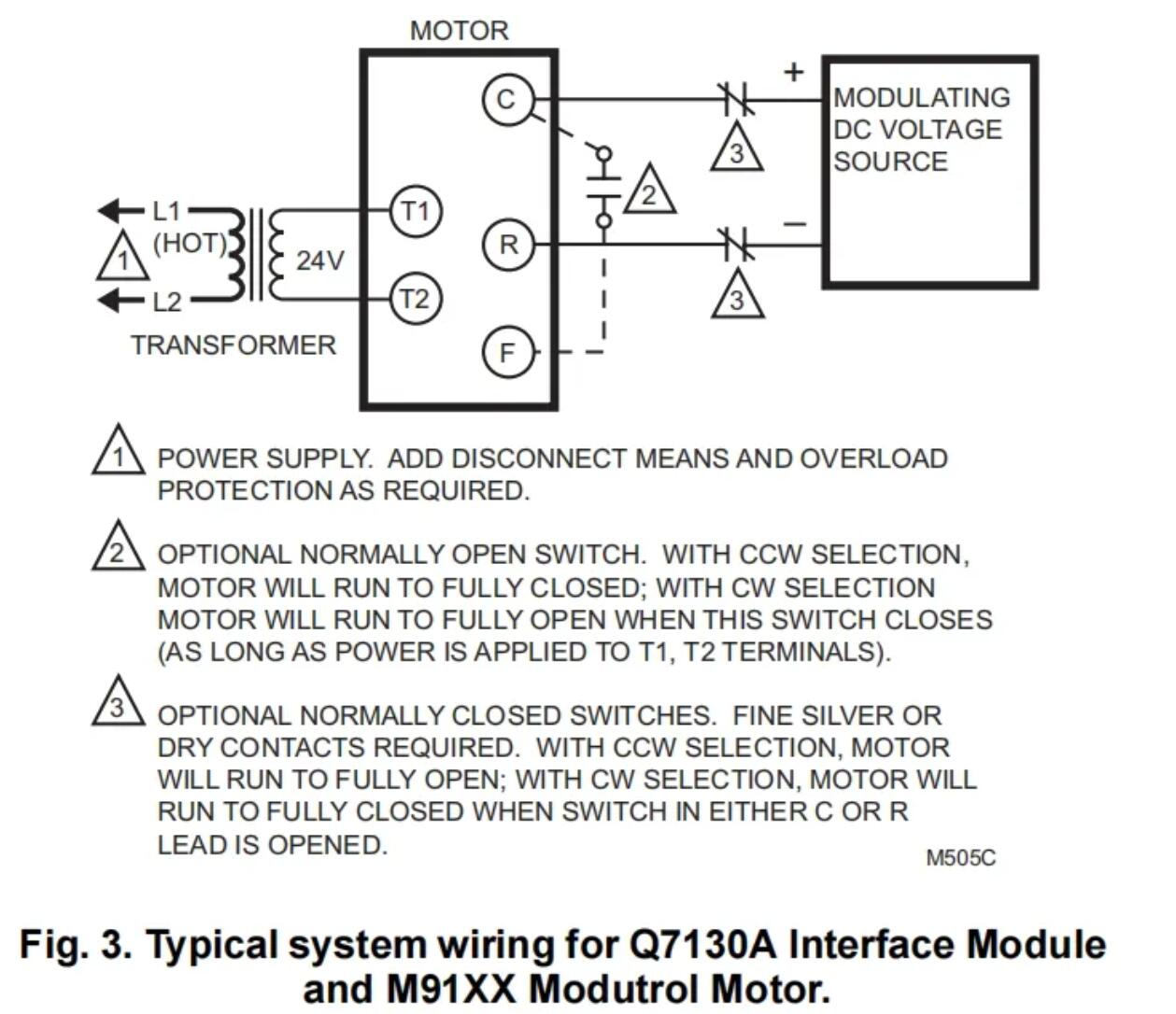

Q7130A Adjustments (Fig. 2)

The Q7130A provides selectable range, two-wire voltage control (4-7, 6-9 or 10.5-13.5 Vdc). It includes a clockwise/ counterclockwise (cw/ccw) switch for replacing electrically normally open or electrically normally closed motors.

1. Select desired voltage range using the three-position switch.

2.Select desired rotation. Select cw for electrically normally closed (motor drives clockwise , as viewed from power end, to open with an increase in control signal). Select ccw for electrically normally open (motor drives counterclockwise , as viewed from powerend, to close with an increase in control signal).

3. See Fig. 3 for typical system wiring.

4. Set controller to drive motor to fully open position and then to fully closed position to check for proper operation.

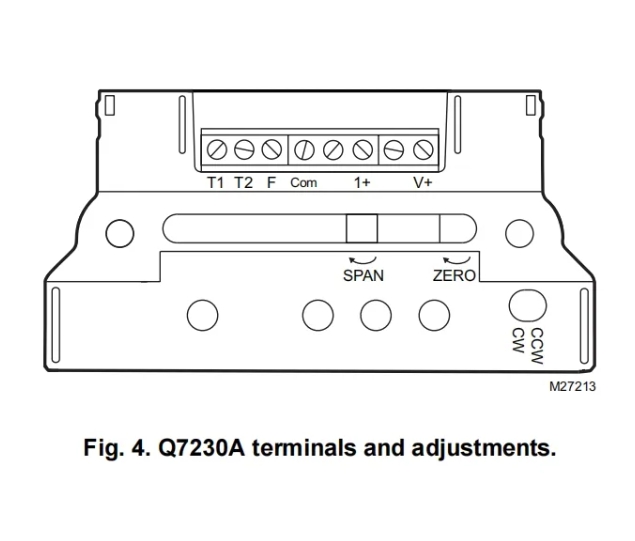

Q7230 Adjustments

The Q7230A provides adjustable range (zero and span) for two-wire current or voltage control. Separate potentiometers are provided on the circuit module for adjusting the zero point and the span. It includes a cw/ccw switch for configuring the motor to rotate clockwise or counterclockwise with an increase in control signal.

1. Verify that the zero potentiometer is fully clockwise and that the span potentiometer is fully counterclockwise.

2. Select desired rotation direction [cw (electrically normally closed) is the most common]. The following directions apply for the clockwise setting. For counterclockwise setting, reverse open and closed, and reverse clockwise and counterclockwise.

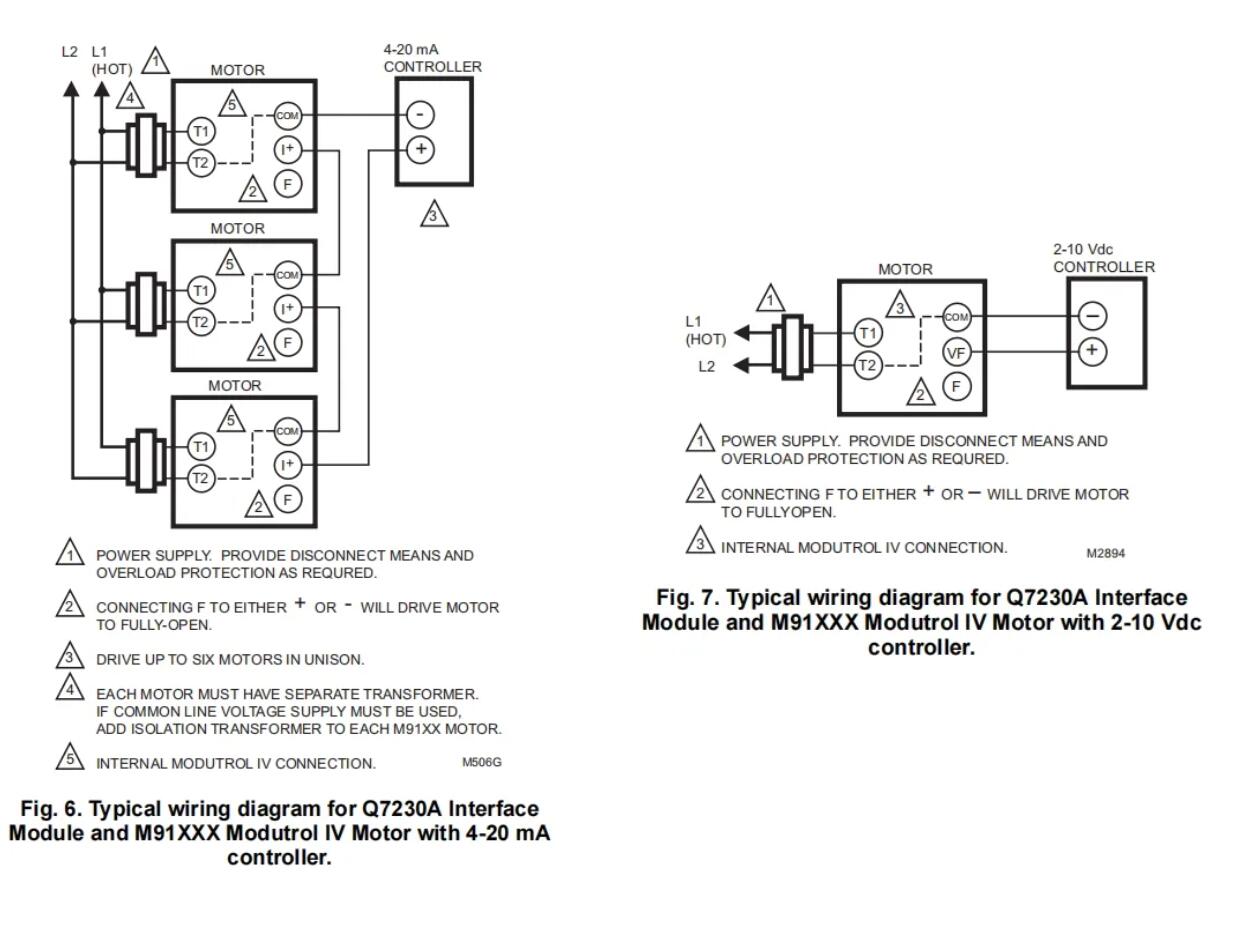

3. See Fig. 6 and 7 for typical system wiring.

4. For current control, connect the current input signal to I+ (screw terminal 3) and COM (screw terminal 5). For voltage control, connect the voltage input signal to V+ (screw terminal 1) and COM (screw terminal 5).

5. Set the controller to output the signal required to drive the motor to the closed position. Wait for the motor to stop driving closed.

6. Turn the zero potentiometer slowly counterclockwise until the motor starts to open.

7. Turn the zero potentiometer slowly clockwise until the motor is fully closed. This is defined as the zero setting.

8. Set the controller to output the signal required to drive the motor to the fully open position. Wait for the motor to stop driving open.

9. Turn the span potentiometer slowly clockwise until the motor starts to drive closed. The difference between the fully open position signal and the fully closed position signal is defined as the operating span.

10. Recheck the fully closed position and readjust the zero potentiometer, if necessary.

(Turn the zero potentiome ter clockwise to close the motor and counter clockwise to open the motor.)

Q7330A Adjustments

The Q7330A provides control interface for W936 and W945 controllers. This module consists only of the terminal block and does not require any adjustments. See Fig. 8 for terminals. After the motor stroke is adjusted (if necessary), simply plug the module onto the motor quick-connect terminals and secure to the motor. See Fig. 9 for typical system wiring.

To check proper motor operation:

1. Provide power to the motor.

2. Jumper terminals 1 and 2 to drive motor open (clockwise as viewed from power end).

3. Jumper terminals 1 and 3 to drive motor closed. Connect field wiring to appropriate screw terminals.

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.