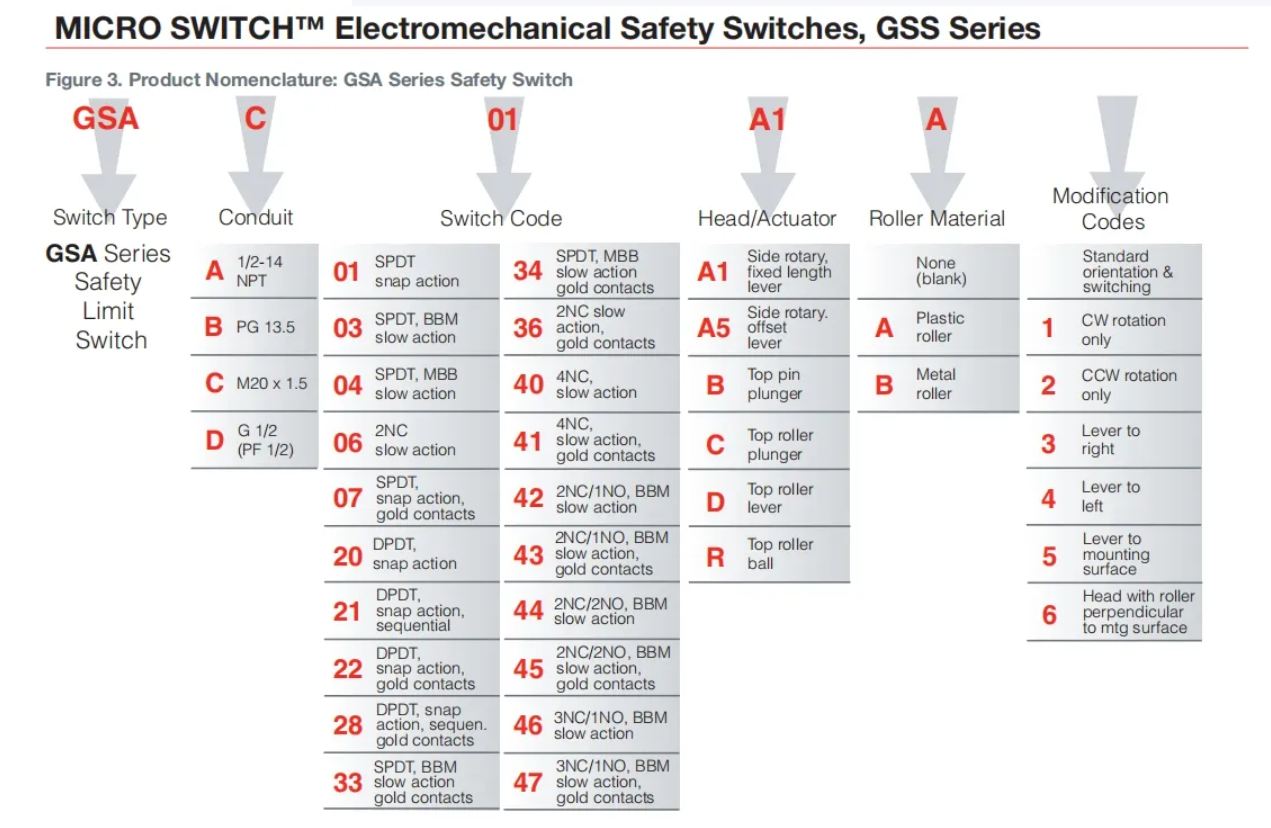

GSAA01C

Product Description

Honeywell's MICRO SWITCH™ GSS Series electromechanical safety switches are comprised of different groups of safety switches designed to either EN50041 or EN50047 standards. GSS Series safety switches are agency certified for global applications, and feature positive opening normally closed contacts . The switch's red body color easily identifies the switch for safety applications. Although these switches are designed for safety applications, they can also be applied in non-safety applications.

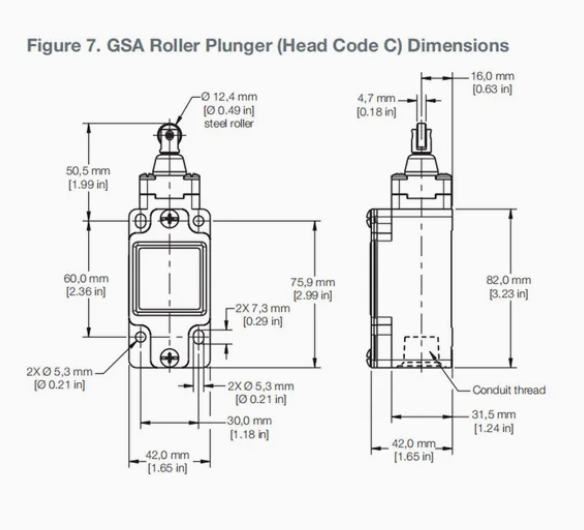

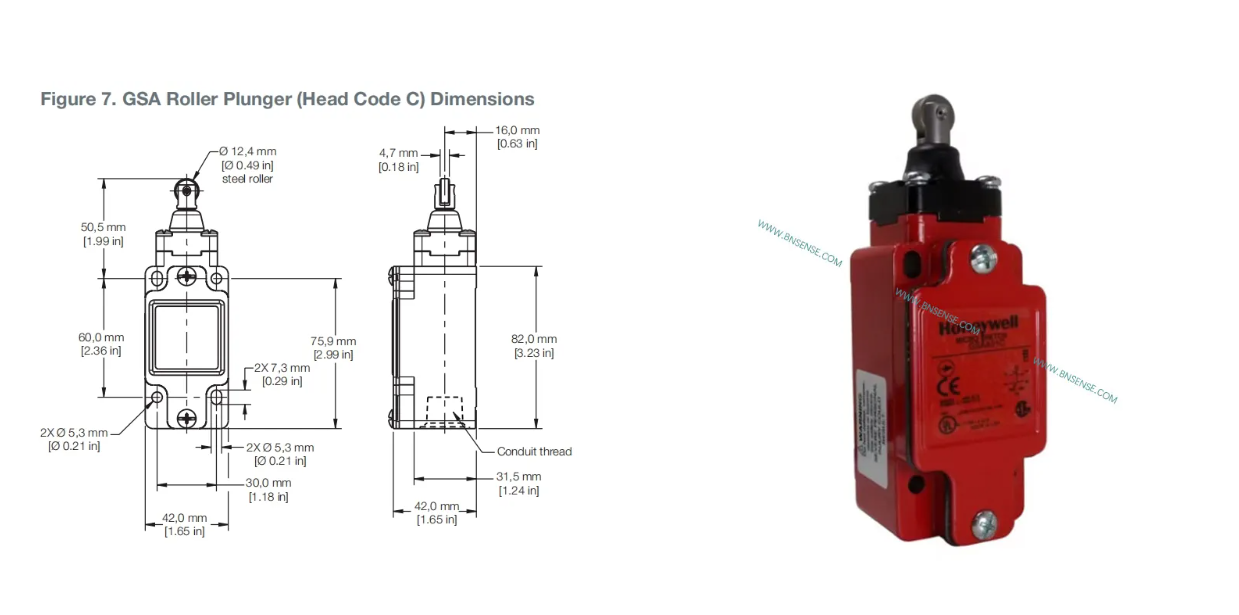

The GSA Series metal limit switches are designed to the EN50041 standard with the 30 mm x 60 mm mounting pattern. Available with up to four contacts and a variety of actuator heads, the GSA Series limit switches are suitable for a wide variety of applications.

The GSC Series and GSE Series metal safety switches are designed with an integral hinge lever. The body of the switch is designed to the EN50047 standard with 20 mm to 22 mm mounting. For applications requiring a similar safety switch to the EN50047 standard with a high-strength thermoplastic housing and the integral hinge lever, the GSD Series safety switch can fill the need for this requirement. Where there is limited space on equipment or machinery, the GSC and GSD Series switches with the smaller housing are the preferred solution. As an alternative, the GSC, GSD, and GSE Series can be supplied with the traditional style of side rotary lever or top plunger actuation.

VALUE TO CUSTOMERS

• Operating heads can be rotated in 90° increments for installation flexibility

• All NC contacts (normally closed contacts) are positive opening when actuated

• Removable contact block for ease of wiring

FEATURES

• Epoxy coated metal zinc housing (GSA Series, GSC Series, or GSE Series)

• Glass-reinforced thermoplastic housing (GSD Series)

• Red body color for easy safety recognition

• Mounting to EN50041 (GSA Series), or EN50047 (GSC Series, GSD Series, and GSE Series)

• Choice of head/actuator types: pin plunger, roller plunger, side rotary standard lever, side rotary offset lever, top roller lever, or hinge lever

• Wide selection of NC (normally closed) and NO (normally open) contact options

• Different threaded conduit options for global applications

• Environmentally sealed for indoor or outdoor applications

• CE, CSA, and UL agency certifications

• Designed and agency evaluated for safety functions up to and including a SIL3 level (GSA and GSD Hinge Lever)

POTENTIAL APPLICATIONS

• Gates, guards, or doors for:

- Agricultural and construction equipment

- Die cast machinery

- Elevators and moving stairs

- Machine tools

- Material handling

- Packaging machinery

- Plastic molding machinery

- Scissor/platform lifts

- Special purpose machinery

DIFFERENTIATION

• Up to four electrically independent contacts for control and monitoring as required

• Gold contacts available for low energy applications

• Side rotary actuator incorporates dual bearing design for increased life

• Specialty contact option, sequential action (GSA Series)

• Catalog listings designed and evaluated up to and including a safety integrity level 3 (SIL3) per IEC 61508-2:2010 (GSA Series and GSD Hinge Lever Series)

SPECIFICATIONS

| Characteristic | Parameter |

| Description | GSA Safety Switch Series: EN50041 mounting (30 mm x 60 mm)GSC/GSD/GSE Safety Switch Series: EN50047 mounting (20 mm to 22 mm) |

| Certifications | CE; DOC # 231, EN/IEC 60947-5-1CSA; File 57323, CSA C22.2 No. 14UL; File E37138, UL508 |

| Housing material | GSA/GSC/GSE Series; electrostatic epoxy coated die-cast zincGSD Series; high strength glass-filled thermoplastic |

| Actuator heads | GSA Series: Side rotary, top pin plunger, top roller plunger, top roller leverGSC/GSD/GSE Series: hinge lever positioned at left, top, or right position |

| Conduit/electrical connection1 | 0.5-14 NPT; 20 mm; PG 13,5; G1/2 (PF1/2) |

| Contact/switch options2 | GLA & GLE Series; 1NC/1NO, 2NC, 2NC/2NO, 3NC/1NO, 4NCGLC & GLD Series; 1NC/1NO, 2NC |

| Contact type | Snap action, snap action sequential (2 step), slow action break-before-make (BBM), slow actionmake-before-break (MBB), slow action |

| Contact design | Double break, electrically separated |

| Contact material | Silver alloy (standard), gold-plated (low energy applications) |

| Utilization category | AC-15, A300/A6003; DC-13, Q300 |

| Rated operational voltage (Ue) | 240 Vac, 600 Vac, 250 Vdc |

| Rated operational current (Ie) | 3 A, 1.2 A, 0.27 A |

| Thermal current (Ith) | 10 A |

| Rated insulation voltage (Ui) | 300 V, 600 V |

| Rated impulse withstandvoltage (Uimp) | 2500 V |

| Short circuit protective device(SCPD) | Class J fuse (10 A/600 V) |

| Pollution degree | 3 |

| Environmental sealing | GSA Series (metal body): IP67, NEMA 1, 4, 12, and 13GSC & GSE Series (metal body): IP66, NEMA 1, 4, 12, and 13GSD Series (plastic body): IP66/67, NEMA 1, 4X (indoor), 12, and 13 |

| Operating temperature | GSA Series with side rotary actuator head: -40 °C to 85 °C [-40 °F to 185 °F]GSA Series without side rotary actuator head: -25 °C to 85 °C [-13 °F to 185°F]GSC/GSD/GSE Series: -25 °C to 85 °C [-13 °F to 185°F] |

| Shock | 50 G per IEC 60068-2-27 |

| Vibration | 10 G per IEC 60068-2-6 |

| MCTF (Mechanical life) | GSA Series: >1,000,000 cycles with single-sided confidence limit of 100%GSD Series (hinge lever actuator): >1,000,000 cycles |

| MCTF (Electrical life) | GSA Series: >25,000 cycles with single-sided confidence limit of 100%GSD Series (hinge lever actuator): >25,000 cycles with single-sided confidence limit of 100% |

| SIL capability | GSA & GSD Series (hinge lever actuator); IEC 61508-2:2010;SIL2 capable with HFT=0*; SIL3 capable with HFT=1* |

| Proof test interval | 1 year |

1 GSE Series has three (3) threaded conduits.

2 All normally closed (NC) contacts are positive opening .

3 A600 for GSA Series only. GSA Series with 2NC contacts (06 or 36 switch code) limited to A300.

* Hardware Fault Tolerance (HFT)

GSA Safety Switch (Top Plunger) with 0.5-14NPT Conduit Order Guide

| CatalogListing0.5-14 NPTConduit* | Head and Lever Type | Contacts | ContactMaterial | OperatingForce max. |

| GSAA01B | Top pin plunger | 1NC/1NO snapaction | Silveralloy | 16 N [3.6 lb] |

| GSAA20B | Top pin plunger | 2NC/2NO snapaction | Silveralloy | 16 N [3.6 lb] |

| GSAA22B | Top pin plunger | 2NC/2NO snapaction | Goldplated | 16 N [3.6 lb] |

| GSAA42B | Top pin plunger | 2NC/1NO slowaction, BBM | Silveralloy | 16 N [3.6 lb] |

| GSAA01C | Top roller plunger | 1NC/1NO snapaction | Silveralloy | 16 N [3.6 lb] |

| GSAA07C | Top roller plunger | 1NC/1NO snapaction | Goldplated | 16 N [3.6 lb] |

| GSAA36C | Top roller plunger | 2NC slowaction | Goldplated | 16 N [3.6 lb] |

| GSAA20C | Top roller plunger | 2NC/2NO snapaction | Silveralloy | 16 N [3.6 lb] |

| GSAA22C | Top roller plunger | 2NC/2NO snapaction | Goldplated | 16 N [3.6 lb] |

| GSAA28C | Top roller plunger | 2NC/2NOsnap action,sequential(2 step) | Goldplated | 16 N [3.6 lb] |

| GSAA43C | Top roller plunger | 2NC/1NO slowaction, BBM | Goldplated | 16 N [3.6 lb] |

| GSAA47C | Top roller plunger | 3NC/1NO slowaction, BBM | Goldplated | 16 N [3.6 lb] |

| GSAA40C | Top roller plunger | 4NC slowaction | Silveralloy | 16 N [3.6 lb] |

| GSAA01D | Top roller lever | 1NC/1NO snapaction | Silveralloy | 9.5 N[2.1 lb] |

| GSAA20D | Top roller lever | 2NC/2NO snapaction | Silveralloy | 9.5 N[2.1 lb] |

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.