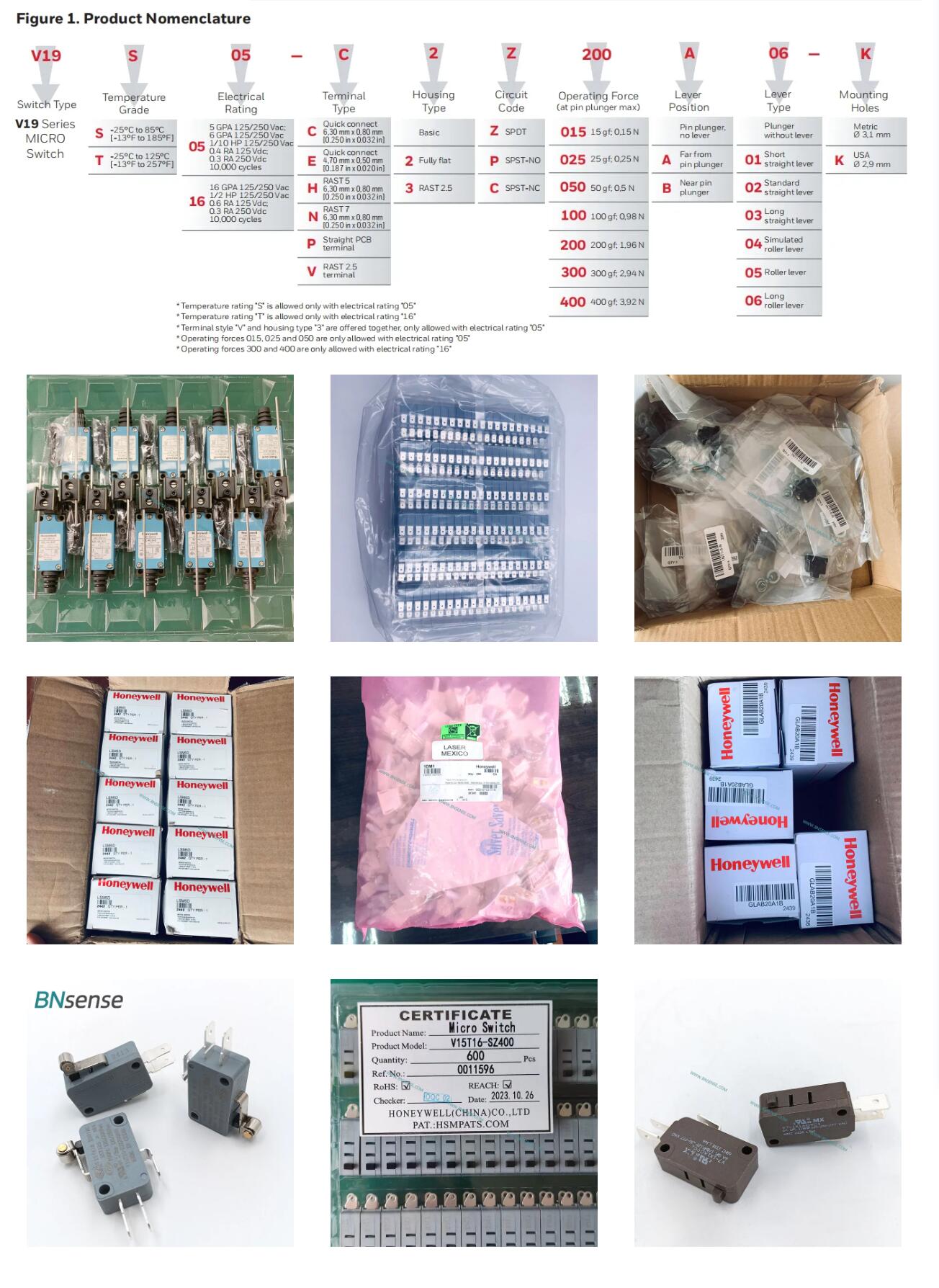

V19S05-HZ015A03

Product Description

ApplicationsPresence Detection: Ensures door latching and safe operationFloat Switch: On/off power to stop overflow conditionsFlow Switch: Enables safe and efficient water usagePower Switch: Reliable systemcontrol for motors, pumps, fans

Operator Controls: Interface controlfor system auxiliary functions

VALUE PROPOSITION

The V19, Honeywell's unsealed MICRO SWITCH family provides a cost-conscious switch solution to assist in hitting overall system-level cost and design goals in high volume applications. The V19 switch provides a fully certified, reliable, and repeatable solution over the lifetime of the product. RAST 2.5, 5, and 7 termination styles available for automated manufacturing requirements (white goods).

| V19 FEATURES 5 A & 16 A | V19 BENEFITSElectrical ratings for design flexibility inone industry standard package size | OUR VALUECompetitive cross references available | ||||||

| > 1M mechanical operations | Globally certified for reliable,repeatable actuation for life | Snap-spring mechanism with more than80 years of MICRO SWITCH service | ||||||

| UL/CSA, cUL, CE, UKCA, ENEC, CQC | Identical system designs for platformapplications worldwide | Certifications enable global designacceptance and cost savingsin agency approvals | ||||||

| Cadmium-free contacts | RoHS 3, REACH andCalProp 65 compliant | |||||||

| RAST 2.5 termination and housing | Enables IDT termination for automatedmachinery builds on signal-level andcontrol circuits | Combined terminal and housingconstruction enables agency certification(UL94V-0 & IEC 60335-1) andmaterial cost savings | ||||||

Unless otherwise stated, all characteristic measurements tested according to UL, EN, and IEC standards and conditions. Parameters and acceptance criteria validated and confirmed in a certified lab environment. Technical details available upon request.

PERFORMANCE SPECIFICATIONS

| CHARACTERISTIC | MEASURE | |

| Circuitry | SPDT, SPNO, SPNC | |

| Operating force | 0,15 N to 3,92 N [15 g to 400 g] | |

| Termination | quick connect; 6,35 mm x 0,80 mm [0.250 in x 0.032 in]quick connect 4,80 mm x 0,50 mm [0.187 in x 0.020 in]RAST-5 250#; RAST-7 250#; RAST-2.5straight PCB | |

| Actuators | pin plunger, integral lever options | |

| Agency certification | ENEC, CQC, UL, cUL, CE, UKCA | |

| Operating temperature(manufacturer specified) | code S: -25°C to 85°C [-13°F to 185°F]code T: -25°C to 125°C [-13°F to 257°F] | |

| Humidity | validated to 240 hours at 40°C [40°F], 95 %RH | |

| Mechanical life (cycles) | 1 million cycles @ 60 cycles/minute max. | |

| Ingress protection rating | IP40 per IEC 60529 | |

| Vibration resistance | 10 Hz to 55 Hz, displacement 1,5 mm (peak-to-peak); no contact separation > 1 millisecond | |

| Shock resistance | destruction: 500 m/s2 (50 g max.); switch is functional after testmalfunction: 100 m/s2 (10 g max.); no contact separation > 1 millisecond | |

| Switch resistance | 50 mΩ max. for opreating force >50; 100 mΩ max. for operating force <50 | |

| Dielectric strength | 1000 Vac (RMS) for 1 minute; leakage current <0.5 mA between open contacts1500 Vac (RMS) for 1 minute, leakage current <0.5 mA between live parts and ground | |

| Insulation resistance | min. 100 mΩ (500 Vdc for one minute) | |

| Contact material | cadmium-free silver alloy | |

| Housing material | PBT thermoplastic polyester | |

| Actuating button material | phenolic | |

| Auxiliary actuator material | stainless steel | |

| Common terminal material | brass | |

| NO/NC terminal material | brass | |

| Moving blade | silver-plated brass | |

| Operating speed | 0,3 mm/s to 1000 mm/s (pin plunger) | |

| Operating frequency | 60 CPM mechanical, 25 CPM electrical | |

| Average unit weight | 7.17g | |

| Packaging dimensions/weight | 505 mm x 310 mm x 225 mm/1900 g | |

ELECTRICAL SPECIFICATIONS

| RATING/NOMENCLATURECODE | UL/CUL (CUL 61058-1, FILE 12252)AMERICAS | ENEC (IEC 61058-1) EUROPECQC (GB15092-1) ASIA-PACIFIC | |||||||||||||||||

| 05 | 5 GPA 125/250 Vac; 6 GPA 125/250 Vac1/10 HP 125/250 Vac0.4 RA 125 Vdc; 0.3 RA 250 Vdc10,000 cycles | 5 (2.5) A 125/250 Vac, 6 (2.5) A 125/250 Vac0.4 A 125 Vdc, 0.3 A 250 Vdc10,000 cycles | |||||||||||||||||

| 16 | 16 GPA 125/250 Vac1/2 HP 125/250 Vac0.6 RA 125 Vdc; 0.3 RA 250 Vdc10,000 cycles | 16 (4) A 250 Vac0.6 A 125 Vdc; 0.3 A 250 Vdc10,000 cycles | |||||||||||||||||

| • RA = Resistive Amps (Resistive Load)• GPA = General Purpose Amps (Inductive Load, 75 % to 80 % power factor)• VL = Lamp Load | • XX (Y) = XX max. resistive value (Amps) and (Y) max. inductive value (Amps) | ||||||||||||||||||

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.