ZLDC04B

Product Description

GENERAL INFORMATION

ZLS series limit switches are specifically designed for worldwide applications and is supported by Honeywell global

resources for sales and after sales service.

ZLS series limit switches are designed to the latest IEC standard are available and include a wide range of EN50041 and EN50047 type switches. Miniature EN50047 limit

switches are available in metal and double insulated enclosures and a metal enclosed 3-cable entry version (EN50047 mounting compatible) is also offered.

Standard ZLS switch circuit variations include 2 and 3-circuit versions with forceddisconnect mechanism. ZLS includes features to make quick installation easier and safer. Customers will benefit from Honeywell's vast experience in serving world industries over many years.

Most ZLS versions are interchangeable with almost all other makes of EN50041/47 switches.

TYPICAL APPLICATIONS

• Machine tools: metal fabrication equipment, presses, transfer lines and special machinery

• Material handling equipment: conveyors, elevators, cranes and hoists

• Packaging machinery and process equipment

• Textile machinery

• Construction machinery and equipment, vehicles and lift trucks

FEATURES

• Designed to the new IEC standard for world-wide applications

• Positive opening of normal closed contact meets IEC947- 5-1-3 safety standard.

• UL, CSA, and CE

• Sealing up to IP/65/ IP 67

• International conduit sizes

• Design for ease of installation

• Eleven basic switch versions, Wide choice of actuators

STANDARDS

IEC 947-1 explains the general rules relating to Low-voltage switchgear and controlgear. The purpose of this standard is to harmonize as much as possible the product performance and test requirements for equipment where the rated voltage does not exceed 1,000 VAC or 1,500 VDC.

IEC 947-5-1 is part 5 of the general rules which relates to Controlcircuit devices and switching elements. Also within this part there is a section which considers Special Requirements. For Control Switches With Positive Opening Operation. Any control switch which has this positive opening operation and conforms to these special requirements will be marked on the outside of the product with this symbol:

The Contact Element Form defines the configuration of the contacts and the number of contacts within the switch. e.g.

Form Za - both contact elements have the same polarity.

Form Zb - the two contact elements are electrically separated.

The Utilization Category defines the type of current carried (AC) Alternating current,(DC) Direct current and the typical application in which the switch is used e.g.

AC15 - Control of Electromagnetic Loads (less than 72VA)

DC13 - Control of electromagnets.

The contact rating Designation relates to the utilization categories and defines the conventional thermal current lth (A), rated operational current le (A) at rated operational voltages Ue and the VA rating e.g.

A600 - The ''A'' denotes the maximum VA rating (AC) and the ''600'' denotes the maximum rated (AC) voltage.

Q300 - The ''Q'' denotes the maximum VA rating (DC) and the ''300'' denotes the maximum rated (DC) voltage.

These IEC standards have been adopted by CENELEC (The European Commitee for Electrotechnical Standardization) and have been identified by replacing IEC with EN 60 e.g.

IEC 947-5-1 then becomes EN 60947-5-1.

CENELEC has defined the dimensions and characteristics of two types of limit switch in the standards EN 50041 and EN 50047. These standards relate to Low voltage switchgear and controlgear for industrial use and define the enclosure dimensions, the operating point for various head actuators, the earth terminal requirement, the terminal marking and the minimum degree of IP protection.

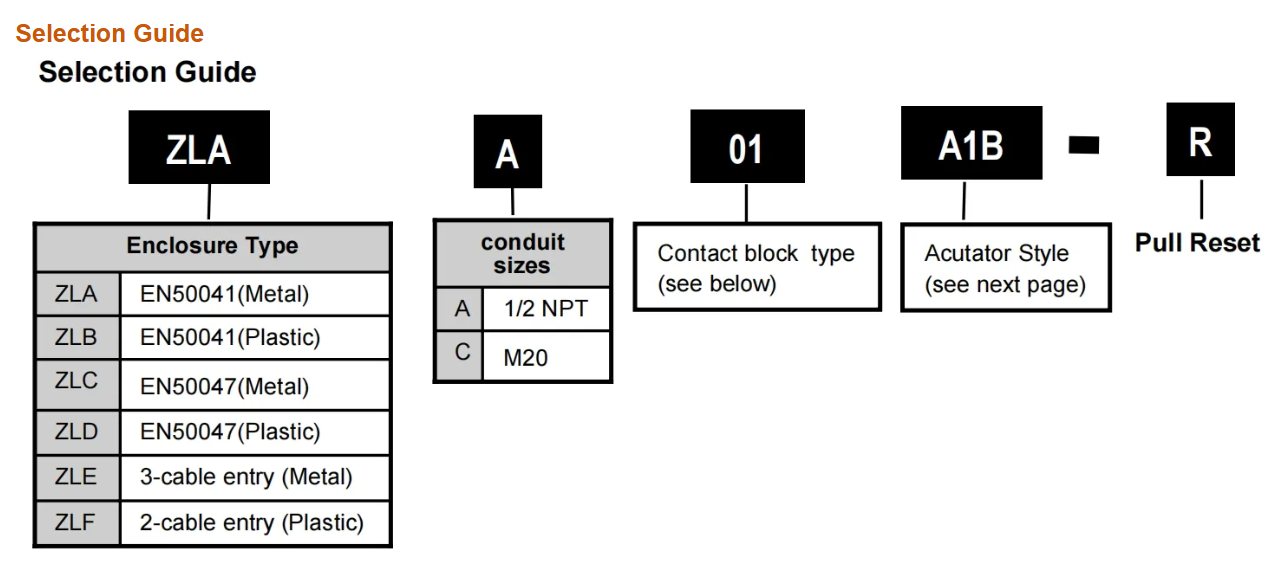

| ZLA | ZLB | ZLC | ZLD | ZLE | ZLF | |||||

| Standard | EN 50041 | EN 50041 | EN 50047 | EN 50047 | EN 500473-cable entry | EN 500472-cable entry | ||||

| Enclosure | Metal | Plastic | Metal | Plastic | Metal | Plastic | ||||

| OperatingTemperature | -25~ +120 °C | -25~ +80 °C | -25~ +80 °C | -25~ +80 °C | -25~ +80 °C | -25~ +80 °C | ||||

| Humidity | <95%RH | <95%RH | <95%RH | <95%RH | <95%RH | <95%RH | ||||

| Shock/Vibration | 10 g / 50 g | 10 g / 50 g | 10 g / 50 g | 10 g / 50 g | 10 g / 50 g | 10 g / 50 g | ||||

| Operating Speed | 0.05mm-2m/s | 0.05mm-2m/s | 0.05mm-2m/s | 0.05mm-2m/s | 0.05mm-2m/s | 0.05mm-2m/s | ||||

| OperatingFrequency | 120 ops/min | 120 ops/min | 120 ops/min | 120 ops/min | 120 ops/min | 120 ops/min | ||||

| Contact Resistance | <25mΩ | <25mΩ | <25mΩ | <25mΩ | <25mΩ | <25mΩ | ||||

| Degree of Protection | IP67 | IP65 | IP67 | IP65 | IP67 | IP65 | ||||

| Electrical Rating | AC15 A600DC13 Q300 | AC15 A300DC13 Q300 | AC15 A300DC13 Q300 | AC15 A300DC13 Q300 | AC15 A600DC13 Q300 | AC15 A300DC13 Q300 | ||||

| Dielectric Strength | 2500V | 2500V | 2500V | 2500V | 2500V | 2500V | ||||

| Mechanical Life | 107 | 107 | 107 | 107 | 107 | 107 | ||||

| Electrical Life | 5X105 | 5X105 | 5X105 | 5X105 | 5X105 | 5X105 | ||||

| Description | Product Attribute |

|---|---|

| Manufacturer | Honeywell |

| Product Category | Basic / Snap Action Switches |

| Contact Form | SPST |

| Switch Function | ON - (OFF) |

| Actuator | Plunger |

| Termination Style | Quick Connect |

| IP Rating | IP65 |

| Actuator Style | Plunger |

| Illuminated | Non-Illuminated |

| Product Type | Snap Action Switches |

| Subcategory | Switches |

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.