U2-1010S-PF

Product Description

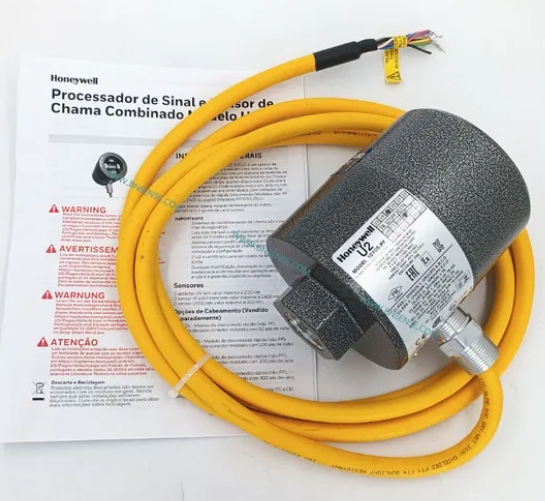

The Honeywell U2-101xS series model is a viewing head and signal processor in a single enclosure intended for use with a burner control system in Industrial Flame Monitoring applications. There are several options available (see Table 1 on page 2). Each model includes one, two, or all three sensors, and can be ordered with quick disconnect (non-PF Models DIV2,ZN2) or pigtail

external connection method (PF Models DIV1,ZN1). Each sensor operates independently from another, allowing adjustment of each sensor.ORDER GUIDE

| Models and Associated Features. | |||||||||

| Model | QuickConnector | Pipe FitConnection | Sensor Type | Typical Fuels | |||||

| UVTron | IR | UVSS | |||||||

| U2-1010S | X | X | X | X | All Fuels | ||||

| U2-1010S-PF | X | X | X | X | All Fuels | ||||

| U2-1010S-PF-050* | X | X | X | X | All Fuels | ||||

| U2-1010S-PF-100 | X | X | X | X | All Fuels | ||||

| U2-1012S | X | X | Oil and Coal | ||||||

| U2-1012S-PF | X | X | Oil and Coal | ||||||

| U2-1016S | X | X | Gas and Light Oils | ||||||

| U2-1016S-PF | X | X | Gas and Light Oils | ||||||

| U2-1018S | X | X | X | All Fuels | |||||

| U2-1018S-PF | X | X | X | All Fuels | |||||

* The U2-1010S-PF-050 has a 50-ft (15m) pigtail and the U2-1010S-PF-100 has a 100-ft (30m) pigtail.

U2-S Model Product DeclarationFIT FOR USE IN A LOW DEMAND SAFETY APPLICATION

Models:U2-1010S, U2-1012S, U2-1016S, U2-1018S, U2-1010S-PF, U2-1012S-PF, U2-1016S-PF, U2-1018S-PF

| Models | SIL | HFT | SFF | PFD | λS | λDD | λDU | |||

| U2-1010S/U2-1010S-PF | 3 | 0 | >99% | 1.20 x10-4 | 1.23x10-5 | 3.34x10-7 | 5.38x10-9 | |||

| U2-1012S/U2-1012S-PF | 3 | 0 | >99% | 1.16x10-4 | 1.64x10-6 | 1.77x10-9 | 5.32x10-9 | |||

| U2-1016S/U2-1016S-PF | 3 | 0 | >99% | 1.15x10-4 | 1.06x10-5 | 1.74x10-9 | 5.27x10-9 | |||

| U2-1018S/U2-1018S-PF | 3 | 0 | >99% | 1.16x10-4 | 1.16x10-5 | 1.77x10-9 | 5.32x10-9 | |||

| System Architecture | 1oo1 | ||||

| MTTR | 8 hours | ||||

| Proof Test Interval | 5 years | ||||

| Fit for use in | SIL 3 environment | ||||

Definitions

| Term | Definition | ||||||||||

| Dangerous Failure | Failure which has the potential to put the safety-related system in a hazardous state | ||||||||||

| Safety-Related System | A system that implements the required safety functions required to achieve or maintain asafe state and is intended to achieve on its own or with other systems the necessary safetyintegrity for the required safety functions. | ||||||||||

| Safety Function | Defined function, which is performed by a safety-related system with the aim of achievingor maintaining a safe state for the plant, in respect of a specified hazardous event. | ||||||||||

| Proof Test | Periodic test performed to detect failures in a safety-related system so that, if necessary, thesystem can be restored to an "as new" condition or as close as practical to this condition. | ||||||||||

| MTTR (Mean Time ToRestoration) | The average duration required for restoration of operations after a failure. | ||||||||||

| λsd | Rate of safe detectable failures per one billion hours.For example, if λsd = 3000, then it is estimated that there will be about 3000 safe detectablefailures during every one billion hours of operation.For λsd = 3000, this is about one safe detectable failure every 38 years. | ||||||||||

| λsu | Rate of safe undetectable failures per one billion hours. | ||||||||||

| λdd | Rate of dangerous detectable failures per one billion hours. | ||||||||||

| λdu | Rate of dangerous undetectable failures per one billion hours. | ||||||||||

| HFT | Hardware Fault Tolerance | ||||||||||

| System Architecture | Specific configuration of hardware and software elements in a system. | ||||||||||

| PFDAVG (AverageProbability of Failure onDemand) | Average Probability of Failure on Demand. | ||||||||||

| FIT (Failures in Time) | A unit of measurement representing one failure per billion hours. 1,000,000,000 hours isapproximately 114,155.25 years. | ||||||||||

SPECIFICATIONS

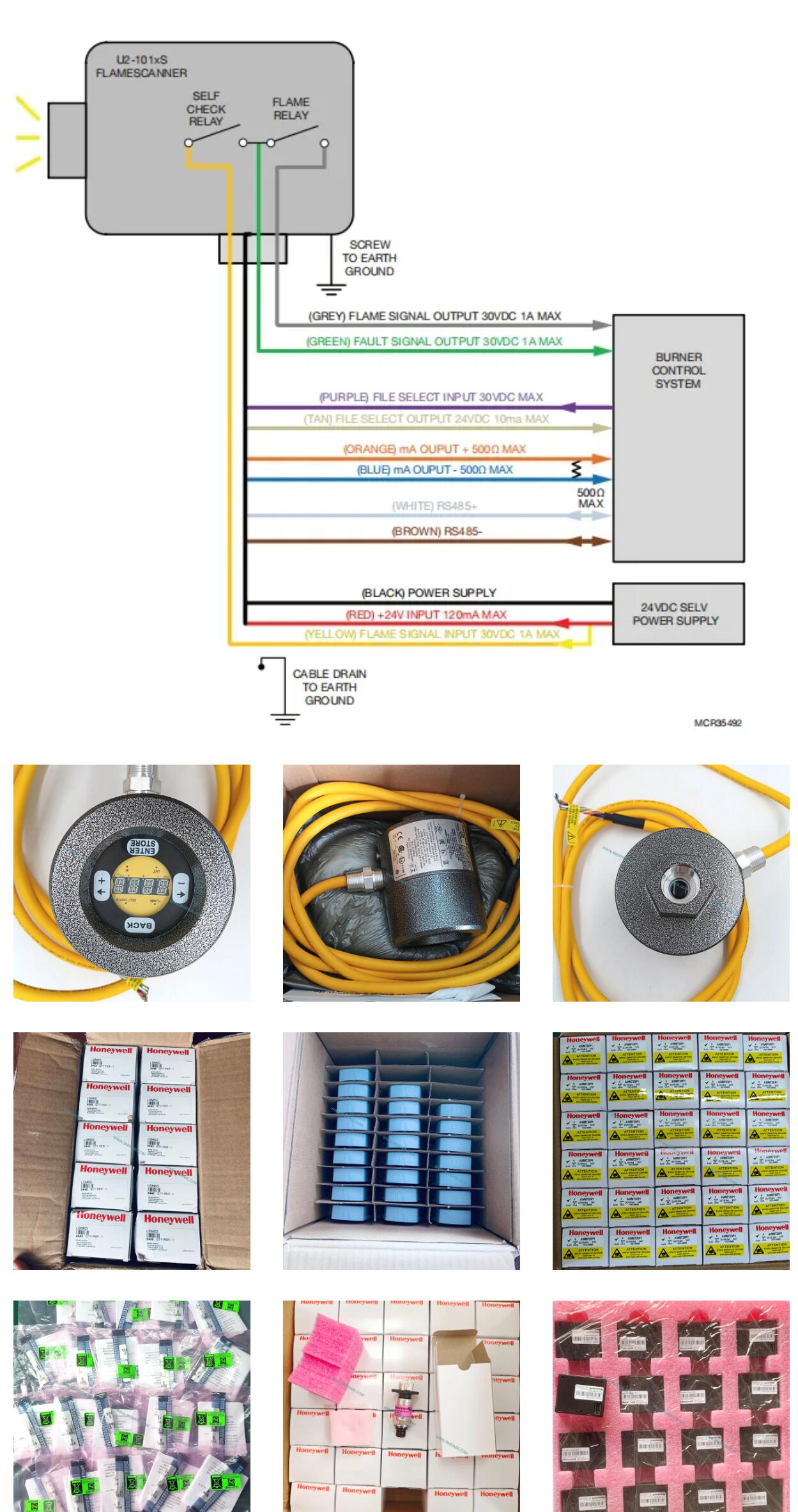

Input Power Supply: 22-26 VDC, 120 mA max (approximately 3.5 watts)

Remote Communication: 2 wire RS485 compatible with Modbus RTU protocol.

Flame And Fault Relay Contact Ratings: 1 A, 30 VDC (Resistive).

Maximum load current of 1A must be de-rated at temperatures higher than 50C ambient according to 1%/C, or 10mA/C. For example, the maximum current at 70C = 1A - (20C x 10mA) = 0.8A.

User Selectable Analog Output: 0-20 mA and 4-20 mA; 500 Ohm Load Max

File Select Input logic high: 21VDC min

File Select Input logic low: 16VDC max

User Interface: Capacitive TouchWheel with LED Display

Ambient temperature: -40 to 70 ºC (-40 to 158 ºF)

Enclosure: IP66

Weight: 2.8 kg (6.1 lbs)

Physical Dimensions: Diameter: 11.7 cm (4.6 inches)

Length: 15.5 cm (6.1 inches)

Finish: Silicone free powder coated

Mounting/Process Connection: 1" NPT female

Pipe Fit Models (PF version): 3/4" NPT

Fuses: Automatically resettable for power source and Flame Relay.

Maximum furnace back pressure: 35 Kg/Cm2 (500 PSI)

Selectable Flame Failure Response Time (FFRT): 1, 2, 3 seconds, Error= +0.0sec, -0.5sec.

Internal Temperature Indication: Degrees C or F in display menu of U2, or available at Modbus register 40019.

Self-Checking

Internal electronic self checking is performed once per second, to verify that system is operating properly. If self check detects an error, the flame relay, and self check relays will open, and the device will display "lockout". This lockout may only be cleared by manual entry reset at the U2 Touchwheel interface.

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.