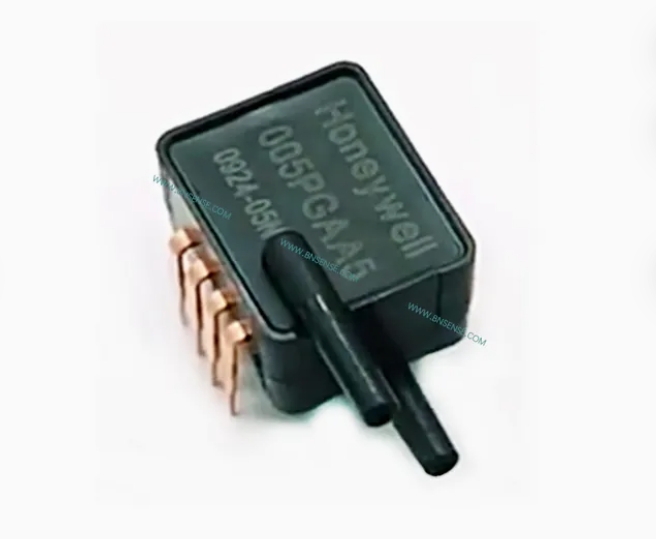

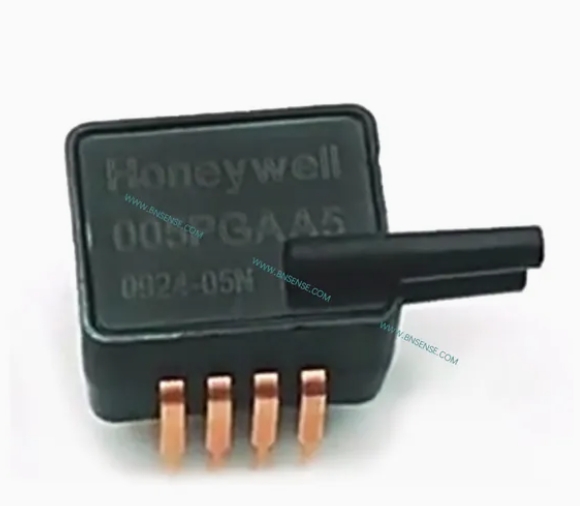

ASDXRRX005PGAA5

Tech Specifications

| Description | Product Attribute |

|---|---|

| Manufacturer | Honeywell |

| Product Category | Board Mount Pressure Sensors |

| Pressure Type | Gauge |

| Operating Pressure | 0 psi to 5 psi |

| Accuracy | 2 % |

| Output Type | Analog |

| Mounting Style | Through Hole |

| Operating Supply Voltage | 5 V |

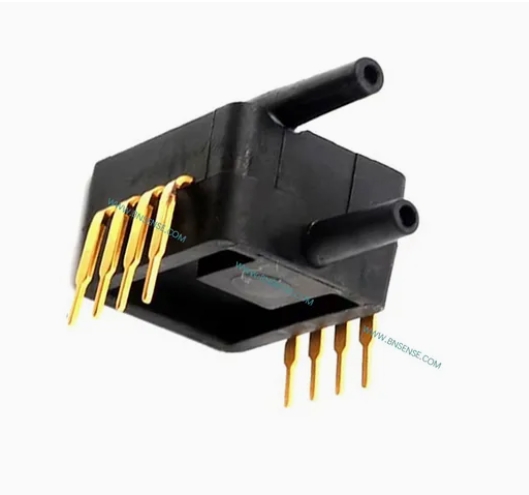

| Port Type | Dual Radial Barbless |

| Package / Case | DIP-8 |

| Minimum Operating Temperature | - 20 C |

| Maximum Operating Temperature | + 105 C |

| Series | ASDX |

| Operating Supply Current | 2.5 mA |

| Port Size | 2.31 mm |

| Product Type | Board Mount Pressure Sensors |

| Subcategory | Sensors |

| Supply Voltage - Max | 5.25 V |

| Supply Voltage - Min | 4.75 V |

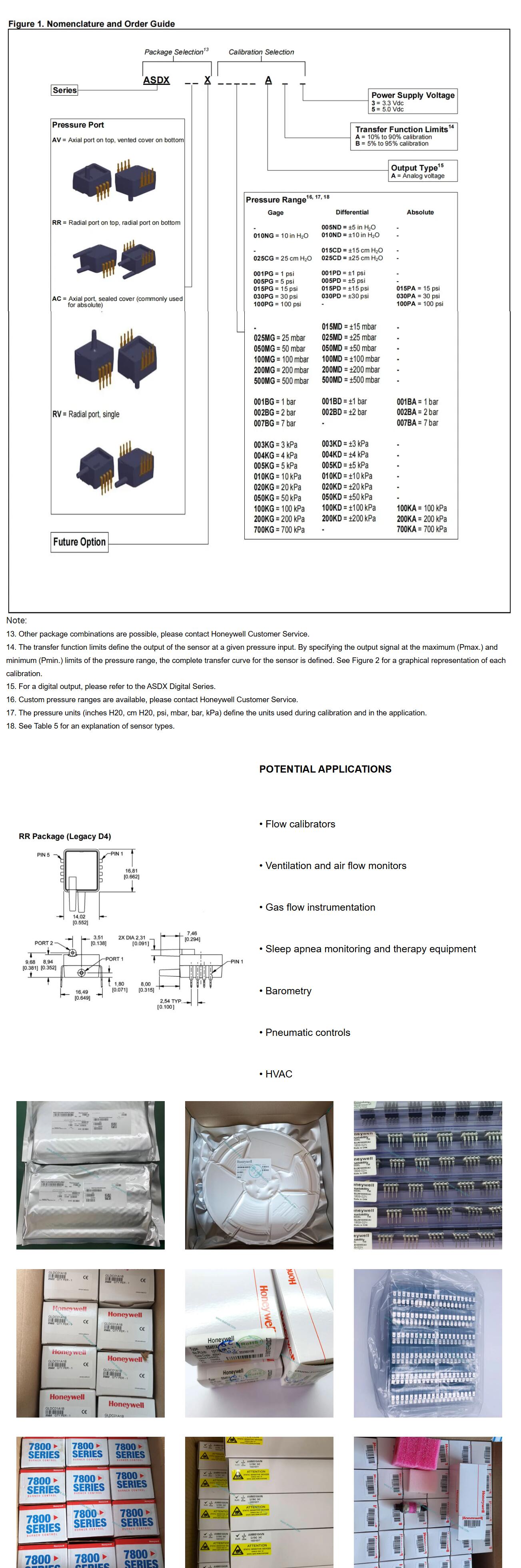

The ASDX Series is a Silicon Pressure Sensor offering a ratiometric analog interface for reading pressure over the specified full scale pressure span and temperature range. The ASDX is fully calibrated and temperature compensated for sensor offset, sensitivity, temperature effects and non-linearity using an on-board Application Specific Integrated Circuit (ASIC). Calibrated output values for pressure are updated at approximately 1 kHz.

The standard ASDX is calibrated over the temperature range of 0 °C to 85 °C [32 °F to 185 °F]. The sensor is characterized for operation from a single power supply of either 3.3 Vdc or 5.0 Vdc.

These sensors are available to measure absolute, differential and gage pressures. The absolute versions have an internal vacuum reference and an output value proportional to absolute pressure. Differential versions allow application of pressure to either side of the sensing diaphragm. Gage versions arereferenced to atmospheric pressure and provide an output proportional to pressure variations from atmosphere.

The ASDX Series sensors are intended for use with noncorrosive, non-ionic working fluids such as air and dry gases. They are designed and manufactured according to standards in ISO 9001.

FEATURES

• Ratiometric 12-bit analog output

• Precision ASIC conditioning and temperature compensated over 0 °C to 85 °C [32 °F to 185 °F]temperature range.

• Low operating voltage

• Absolute, differential and gage types

• Pressure ranges from 10 inches H20 to 100 psi

• Standard calibrations in inches H20, cm H20, psi, mbar, bar, kPa

• Total error band of ±2.0% of full scale span maximum

• RoHS compliant

POTENTIAL APPLICATIONS

• Flow calibrators

• Ventilation and air flow monitors

• Gas flow instrumentation

• Sleep apnea monitoring and therapy equipment

• Barometry

• Pneumatic controls

• HVAC

| Parameter | Min | Max | Unit | ||||

| Supply voltage (Vsupply) | -0.3 | 6.0 | Vdc | ||||

| Voltage to any pin | -0.3 | Vsupply + 0.3 | Vdc | ||||

| ESD susceptibility (human body model) | 3 | - | kV | ||||

| Storage temperature | -50 [-58] | 125 [257] | °C [°F] | ||||

| Lead temperature (2 s to 4 s) | - | 250 [482] | °C [°F] | ||||

| External capacitance between Vsupply and ground2 | 100 | 470 | nF |

Operating Specifications

| Parameter | Min. | Typ. | Max. | Unit | |||

| Supply voltage: (Vsupply)3 3.3 Vdc 5.0 VdcSensors are either 3.3 Vdc or 5.0 Vdc per the order guide (see Figure 1). | 3.04.75 | 3.345.04 | 3.65.25 | Vdc | |||

| Supply current | 1.5 | 2.5 | 3.5 | mA | |||

| Compensated temperature range5 | 0 [32] | - | 85 [185] | °C [°F] | |||

| Operating temperature range6 | -20 [-4] | - | 105 [221] | °C [°F] | |||

| Overpressure7 | 2X operating pressure range minimum | ||||||

| Burst pressure8 | 3X operating pressure range minimum | ||||||

| Startup time (power up to data ready) | - | - | 5 | ms | |||

| Response time | - | 1.0 | - | ms | |||

| Upper output clipping limit | 97.5 | - | - | Vsupply | |||

| Lower output clipping limit | - | - | 2.5 | Vsupply | |||

| Minimum load resistance | 5.0 | - | - | kOhm | |||

| Total error band9 | - | - | 2.0 | %FSS10 | |||

| Output resolution | 12 | - | - | bits | |||

Environmental Specifications

| Parameter | Characteristic | ||||||

| Humidity | 0% to 95% RH non-condensing | ||||||

| Vibration | 10 G at 20 Hz to 2000 Hz | ||||||

| Shock | 100 G for 11 ms | ||||||

| Life | 1 million cycles minimum | ||||||

Wetted Materials11

| Parameter | Port 1 (Pressure Port)12 | Port 2 (Reference Port)12 | |||||

| Covers | glass-filled PBT | glass-filled PBT | |||||

| Adhesives | silicone | silicone and epoxy | |||||

| Electronic components | silicon and glass | silicon, glass, and gold | |||||

Notes:

1. Absolute maximum ratings are the extreme limits that the device will withstand without damage to the device.

2. An external bypass capacitor is required across the supply voltage (Pins 1 and 3 - see Figure 4) as close to the sensor supply pin as possible for correct sensor operation.

3. Ratiometricity of the sensor (the ability of the output to scale to the input voltage) is achieved within the specified operating voltage for each

option. Other custom supply voltages are available, please contact Honeywell Customer Service.

4. The sensor is not reverse polarity protected. Incorrect application of excitation voltage or ground to the wrong pin may cause electrical failure.

5. The compensated temperature range is the temperature range (or ranges) over which the sensor will produce an output proportional to pressure within the specified performance limits.

6. The operating temperature range is the temperature range over which the sensor will produce an output proportional to pressure but may not

remain within the specified performance limits.

7. Overpressure is the maximum pressure which may safely be applied to the product for it to remain in specification once pressure is returned to the operating pressure range. Exposure to higher pressures may cause permanent damage to the product.

8. Burst pressure is the maximum pressure that may be applied to any port of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

9. Total error band is the maximum deviation in output from ideal transfer function over the entire compensated temperature and pressure range.

Includes all errors due to offset, full scale span, pressure non-linearity, pressure hysteresis, repeatability, thermal effect on offset, thermal effect

on span and thermal hysteresis. Specification units are in percent of full scale span (%FSS).

10. Full scale span (FSS) is the algebraic difference between the output signal measured at the maximum (Pmax.) and minimum (Pmin.) limits of the pressure range.

11. Consult Honeywell Customer Service for detailed material information.

12. For AC pressure port configuration, the "pressure" and "reference" ports are reversed.

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.